Stress-Strain Graphs (Edexcel International A Level (IAL) Physics) : Revision Note

Stress-Strain Graphs

Stress-strain curves give an indication of the properties of materials such as

Up to what stress and strain they obey Hooke's Law

Whether they exhibit elastic and/or plastic behaviour

The value of their Young Modulus

The value of their breaking stress

Each material has a unique stress-strain curve

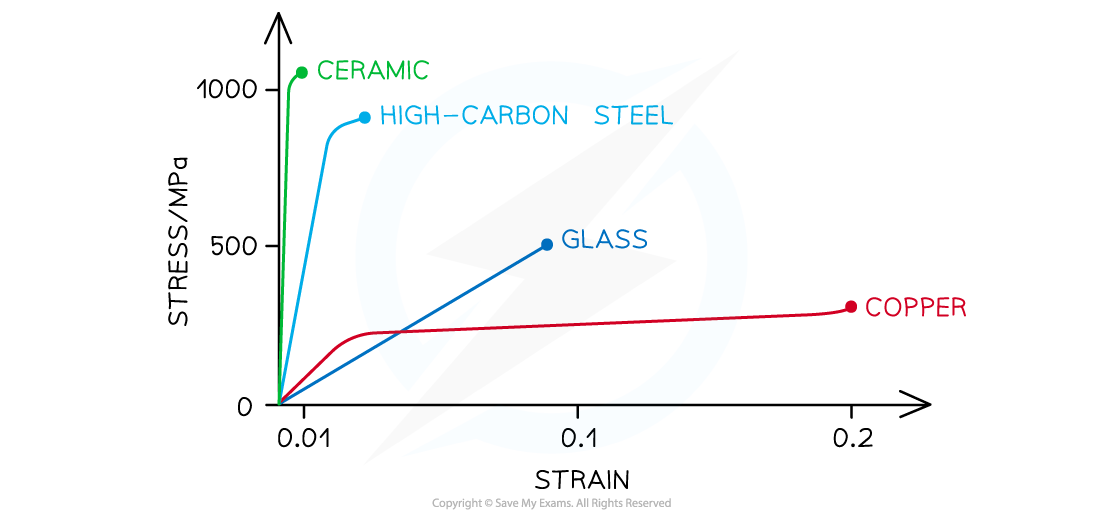

Stress-strain graph for different materials up to their breaking stress

Comparing Force-Extension to Stress-Strain Graphs

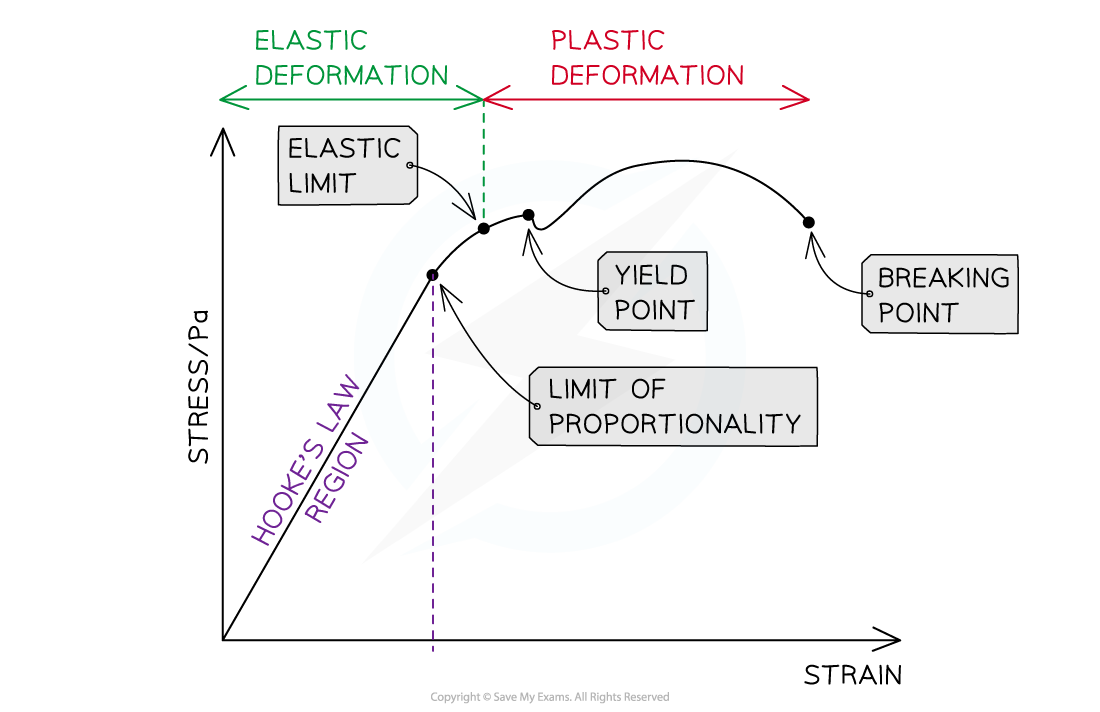

The key features of the graph which are also on the force-extension graph are:

Limit of proportionality, beyond which Hooke's law no longer applies

The elastic limit, before which a material returns to its original length or shape when the deforming force is removed

The yield point beyond which the material continues to stretch (more strain is seen) even though no extra force is being applied to it (without additional stress)

Elastic deformation where the material will return to its original shape when the load is removed

Plastic deformation where the material will not return to its original shape when the load is removed

The important points shown on a stress-strain graph

The stress-strain graph is also used to find;

The Young Modulus is found from the gradient of the straight part of the graph

Breaking stress (also called fracture stress) is the stress at the point where the material breaks

At the yield point the atoms in the material had started to move relative to each other, at the breaking stress they separate completely

Breaking stress is not the same as ultimate tensile stress which is marked on many graphs

Worked Example

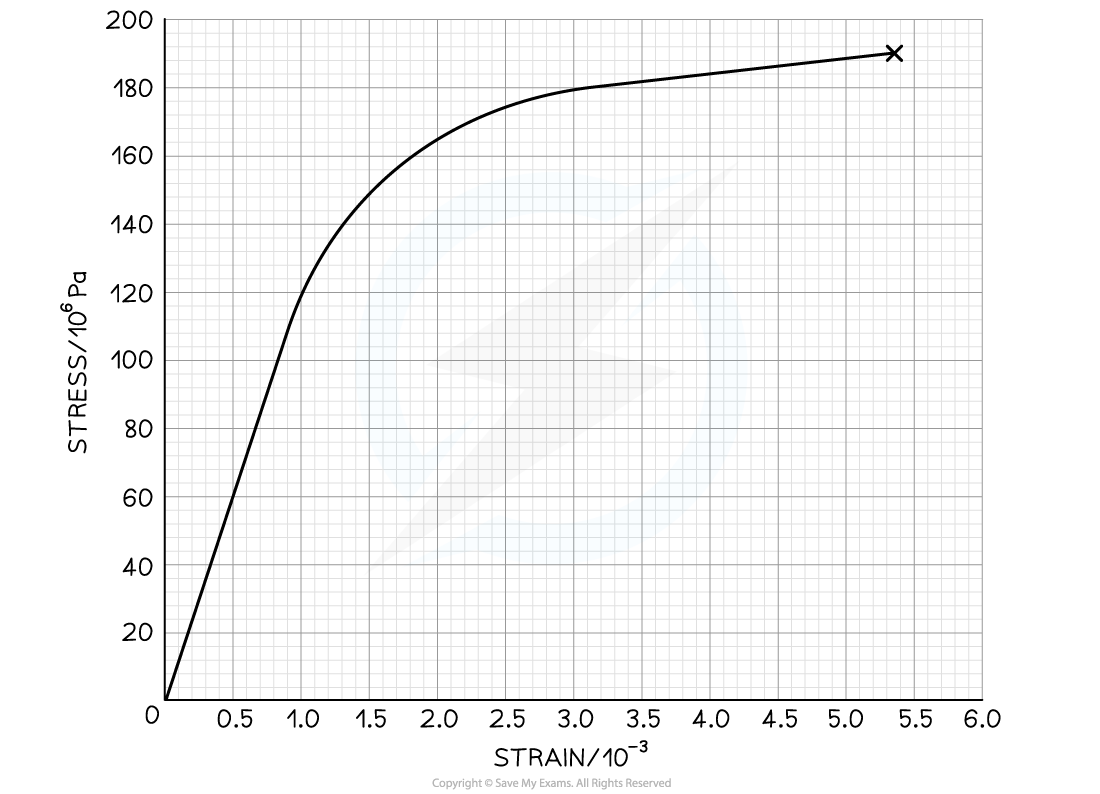

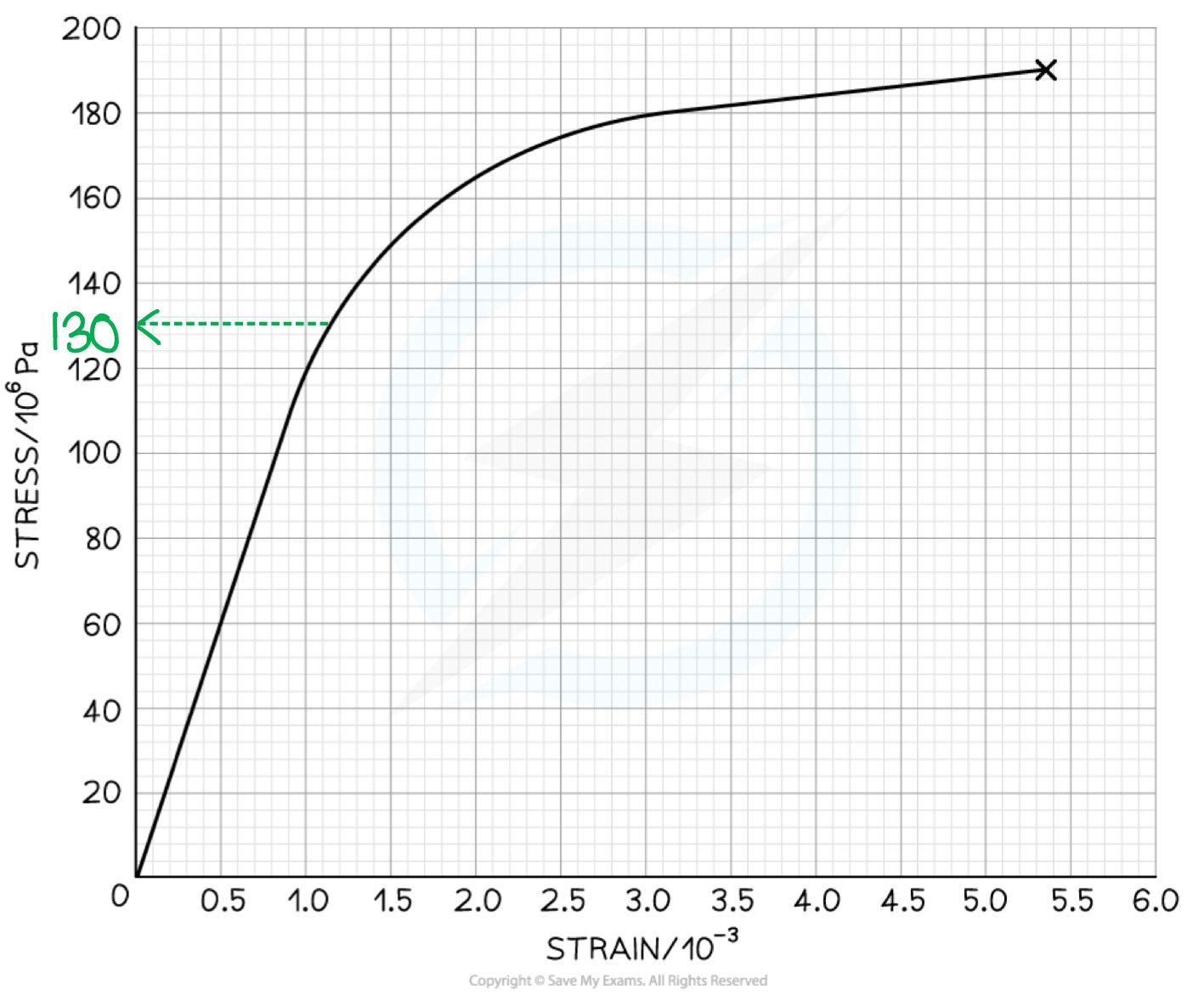

The graph below shows a stress-strain curve for a copper wire.

From the graph, state the value of:

(a) The breaking stress

(b) The stress at which plastic deformation begins

Answer:

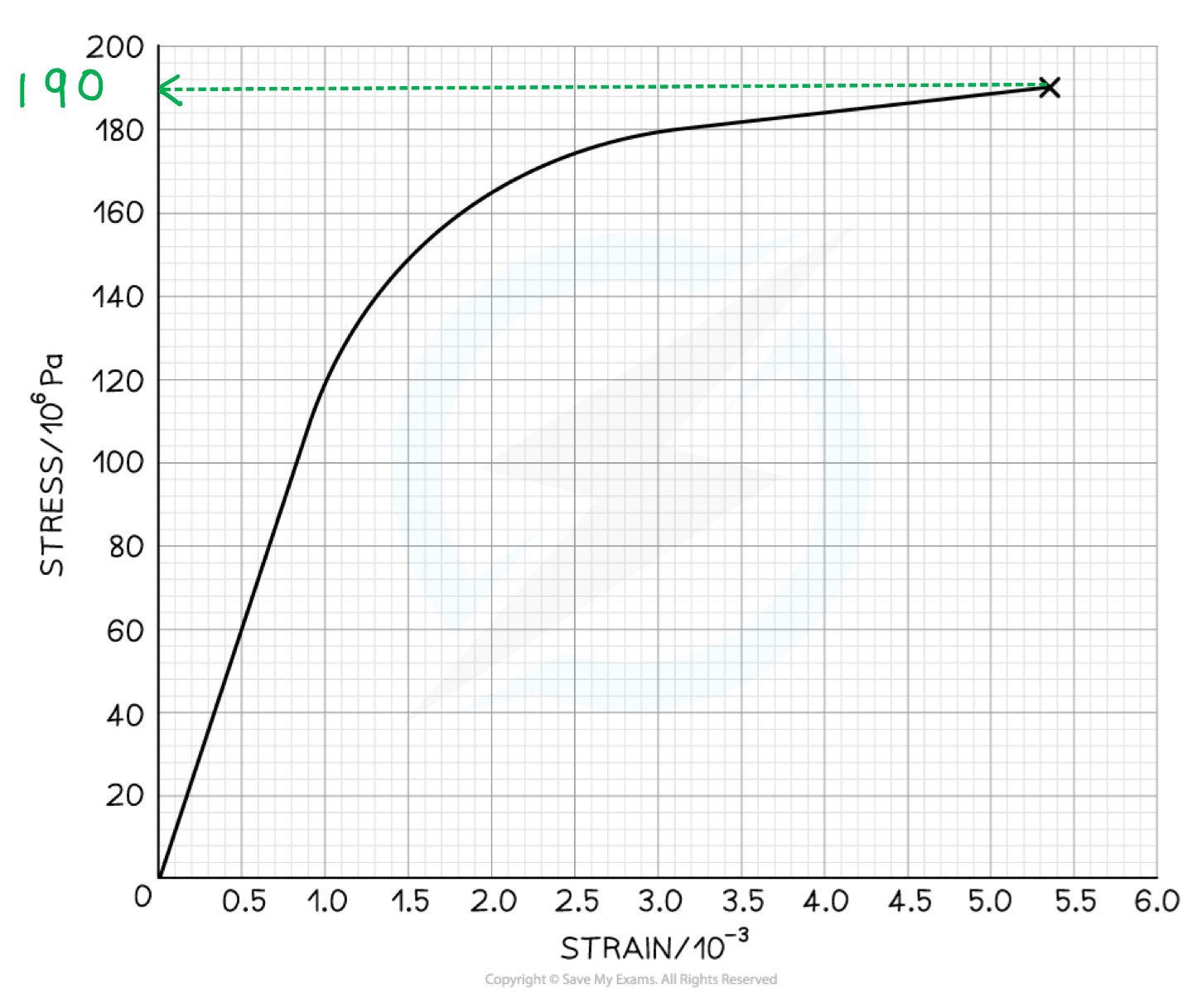

Part (a)

Step 1: Define breaking stress

The breaking stress is the maximum stress a material can stand before it fractures. This is the stress at the final point on the graph

Step 2: Determine breaking stress from the graph

Draw a line to the y axis at the point of fracture

The breaking stress is 190 MPa

Part (b)

Step 1: Define plastic deformation

Plastic deformation is when the material is deformed permanently and will not return to its original shape once the applied force is removed

This is shown on the graph where it is curved

Step 2: Determine the stress of where plastic deformation beings on the graph

Draw a line to the y axis at the point where the graph starts to curve

Plastic deformation begins at a stress of 130 MPa

Examiner Tips and Tricks

It is a very common exam question to be asked to define some of the key points on this graph, or to identify them from a graph.

Make sure you have cleared up exactly what the differences are between the limit of proportionality, elastic limit and yield point. It's easy to get confused between them so practice sketching the graph, and labelling the points with their definitions.

You've read 1 of your 5 free revision notes this week

Unlock more, it's free!

Did this page help you?