Galvanising & Sacrificial Protection (Cambridge (CIE) IGCSE Chemistry): Revision Note

Exam code: 0620 & 0971

Did this video help you?

Galvanising & sacrificial protection

Extended tier only

Sacrificial Protection

Iron can be prevented from rusting using the reactivity series

A more reactive metal can be attached to a less reactive metal

The more reactive metal will oxidise and therefore corrode first, protecting the less reactive metal from corrosion

Zinc bars on the side of steel ships

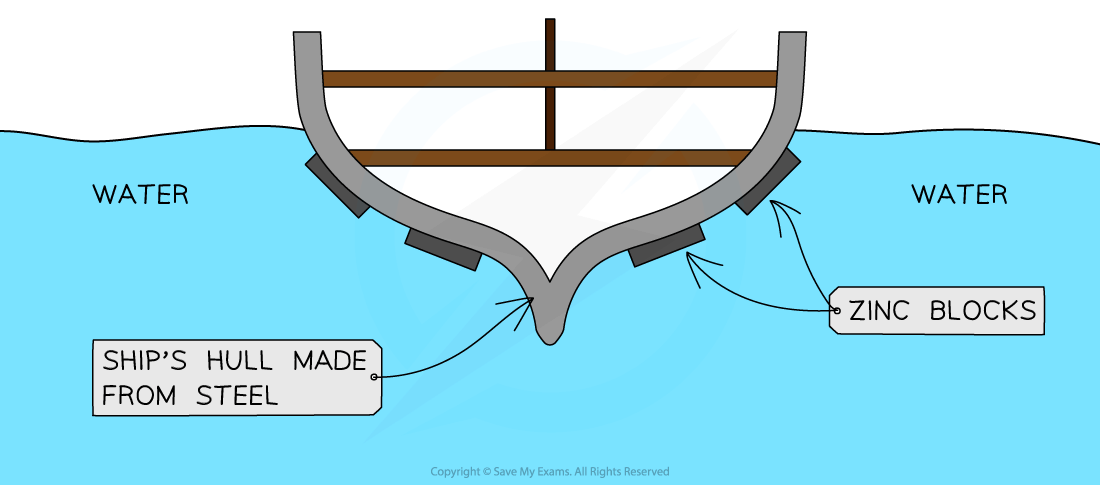

Diagram to show the use of zinc bars on the sides of steel ships as a method of sacrificial protection

Zinc is more reactive than iron therefore will lose its electrons more easily than iron and is oxidised more easily:

Zn → Zn2+ + 2e-

The iron is less reactive therefore will not lose its electrons as easily so it is not oxidised; the zinc is sacrificed to protect the steel

The zinc blocks do not need to cover the whole hull

As long as they are electrically connected to the steel, they can protect nearby areas

They are often placed on edges and joints where corrosion is most likely.

For continued protection, the zinc bars have to be replaced before they completely corrode

Galvanising

Galvanising is a process where the iron to be protected is coated with a layer of zinc

This can be done by electroplating or dipping it into molten zinc

ZnCO3 is formed when zinc reacts with oxygen and carbon dioxide in the air and protects the iron by the barrier method

If the coating is damaged or scratched, the iron is still protected from rusting by sacrificial protection

Examiner Tips and Tricks

You maybe asked to explain why a metal is/is not suitable as a method of preventing an iron/steel object from rusting. Remember that if it is higher in the reactivity series than iron, it will be suitable for sacrificial protection as it will be oxidised instead of iron. If it is lower in the reactivity series than iron, it would not be suitable as iron would be oxidised, causing it to rust.

Unlock more, it's free!

Was this revision note helpful?