Principles of Lean Production (Edexcel IGCSE Business): Revision Note

Exam code: 4BS1

Introduction to lean production

Lean production involves the minimisation of the resources used in production

Less time is required as the production process is organised in the most efficient way

Fewer materials are used as there is a focus on waste reduction

Less labour is used as lean production is typically capital intensive

The space required for production is reduced as a result of just in time stock management

A small number of trusted suppliers work closely with the business

The use of lean production is likely to lead to a competitive advantage

Lower unit costs are achieved due to minimal wastage so prices may be lower than those offered by competitors

High quality output is likely as a result of supplier reliability and carefully managed production processes

The result should be increased profit margins

Lean production uses strategies such as Just in Time stock control and Kaizen

Just-in-time (JIT) stock management

Just-in-time (JIT) stock management is a process in which raw materials are not stored onsite but ordered as required and delivered by suppliers 'just in time' for production

Careful coordination is required to ensure that raw materials and components are delivered by suppliers at the moment that they are to be used

Close relationships with suppliers need to be developed

Suppliers may need to be in close proximity

Just-in-time is particularly useful for businesses that operate in dynamic markets

Products may need frequent design changes that require different components

Holding large amounts of stock risks wastage through obsolescence

Where significant competition exists lean production can ensure a high level of quality to achieve a competitive advantage

Advantages and disadvantages of just-in-time stock management

Advantages | Disadvantages |

|---|---|

|

|

Kaizen

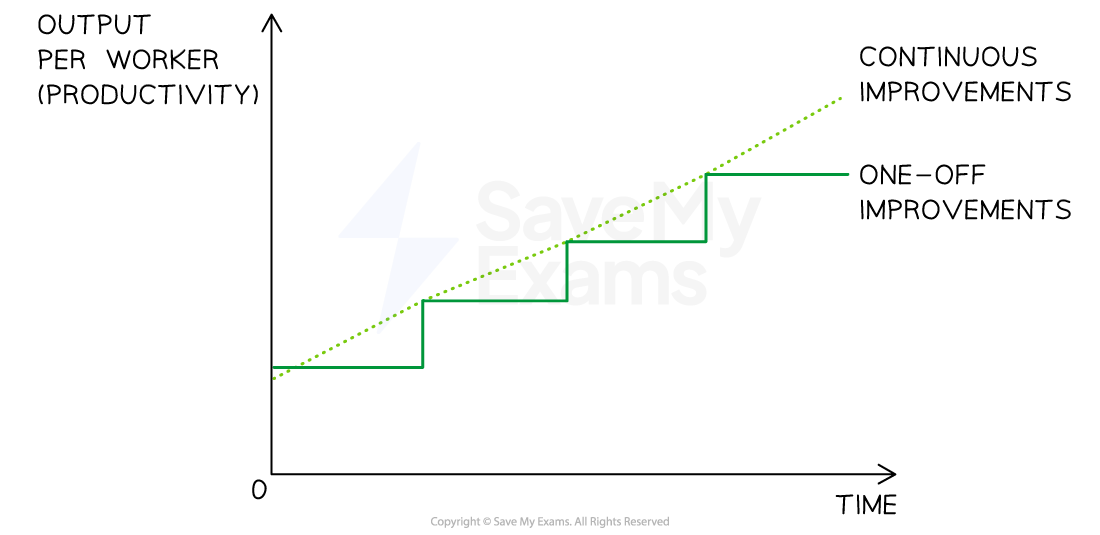

Kaizen involves taking continuous steps to improve productivity through the elimination of all types of waste in the production process

Changes are small and ongoing rather than significant one-off’s

They are constantly reviewed to ensure that they achieve the desired positive impact on productivity and always focused on meeting customers' needs

Kaizen requires a long-term cultural and management commitment to change

All workers must be actively involved in making improvements, not just management

Ongoing training and development is vital

The impact of Kaizen on productivity over time

Elements of Kaizen commonly include

Zero defects in manufacturing

High levels of automation

High levels of cooperation between workers and management

Employees are likely to work in teams and be empowered to work creatively

Staff training and computer inventory management systems may also reduce wastage as fewer errors are likely to be made

Examiner Tips and Tricks

In the exam, you could be asked to justify whether a business should improve efficiency by adopting just-in-time or kaizen. A great evaluation point is that, in most cases, the two elements of lean production are adopted together.

The importance of using resources effectively

Lean production is focused on the effective use of resources and, in particular, the elimination of waste throughout the business

Waste refers to anything that prevents a business from being efficient

Seven key types of waste are minimised in lean production

The seven wastes

Transportation: Unnecessary movement of materials or products

Inventory: Excess raw materials, work-in-progress, or finished goods

Motion: Unnecessary movement of people or equipment

Waiting: Delays or idle time in the production process

Overproduction: Producing more than what is required by the customer

Overprocessing: Using more resources than necessary to produce a product

Defects: Products or services that do not meet customer requirements

Benefits of reducing waste

Benefit | Explanation |

|---|---|

Competiveness |

|

Lower costs |

|

Better customer service |

|

Environmental benefits |

|

You've read 0 of your 5 free revision notes this week

Unlock more, it's free!

Did this page help you?