Quality Management (DP IB Business Management) : Revision Note

An Introduction to Quality Management

Quality management involves a business carefully considering the characteristics and features of a product that satisfy the needs of customers and ensuring that it has effective systems and procedures to meet these

Businesses need to maintain a level of quality that continues to attract and retain customers if they want to remain successful

Customer perceptions of quality are related to a range of product or business features

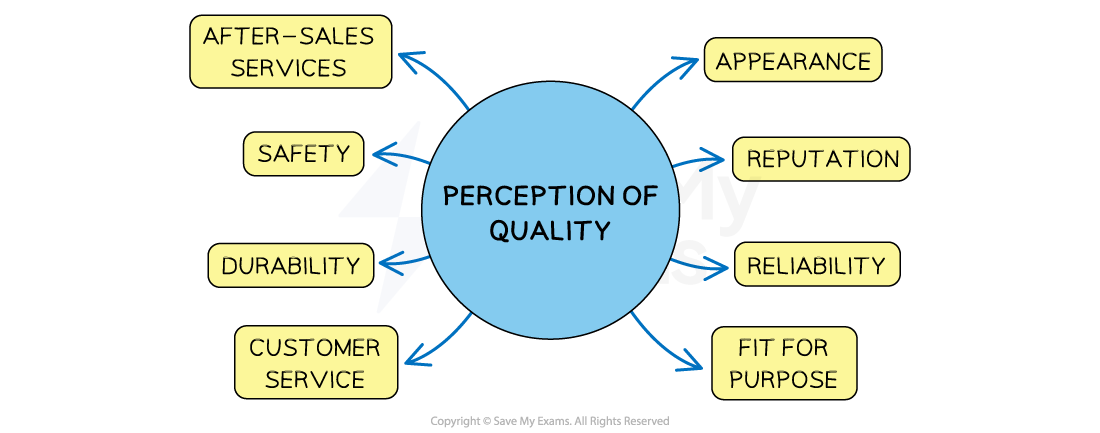

Diagram: factors that influence quality perception

Customers may consider products or services to be of good quality if they

Look good and are sold by a reputable business or brand

Are reliable and durable

Are safe and fit for purpose

Receive good customer service, including after-sales service

Examiner Tips and Tricks

High quality may provide justification to charge a premium price for products

However, it is not always the case that good quality leads to increased sales

For many customers as long as a product's quality is 'good enough' they will be reluctant to upgrade to a more prestigious brand, especially when their incomes are squeezed

Measuring Quality

Businesses can measure the quality of their output in a range of ways

Reject Rates | Product Returns | Product Recalls |

|---|---|---|

|

|

|

In addition factors such as customer satisfaction, customer loyalty and market share can provide useful indications of customer experiences and perceptions of quality

Customers satisfied with quality are less likely to make complaints and are likely to give positive feedback in surveys

High quality can drive repeat purchases

Increased market share may demonstrate satisfaction with quality over that offered by rival products/services

Categories of Quality Management

A businesses approach to quality management falls into one of two categories

Quality control involves inspecting the quality of output at the end of the production process

Workers focus on maximising output

Products that do not meet standards are rejected before they are released for sale

Quality assurance involves inspecting the quality of production throughout the process

Workers check their own work and, sometimes, the work of others at various stages of production

Some business take a whole business approach to quality assurance with systems such as quality circles, benchmarking and Total Quality Management (TQM)

An Evaluation of Approaches to Quality Management

Method | Benefits | Drawbacks |

|---|---|---|

Quality Control |

|

|

Quality Assurance |

|

|

Quality Assurance Using Quality Circles

Quality circles involve groups of workers meeting regularly to identify and solve quality problems in the production process

Groups are made up of volunteers from different departments

Meetings are typically chaired by a senior leader

Members work together to execute and manage solutions

An Evaluation of Quality Circles

Advantages | Disadvantages |

|---|---|

|

|

Quality Assurance Using Benchmarking

Benchmarking involves a business comparing its quality and performance with market leaders within the same industry

Benchmarking can be internal or external

Internal benchmarking

Comparison of different functions within a business such as finance and marketing

Performance

Comparison of key performance indicators such as labour productivity or labour turnover rates

Process

Comparison of business operations and processes such as call centre queue times or delivery times

External benchmarking

Comparison of key performance indicators (such as product recalls) against those of market leaders in an industry

International benchmarking compares key performance indicators against those of market leaders overseas

An Evaluation of Benchmarking

Advantages | Disadvantages |

|---|---|

|

|

Quality Assurance Using Total Quality Management (TQM)

Total Quality Management (TQM) places quality at its core and makes every worker responsible for quality throughout the business

Quality is considered from the customer's perspective

Inefficiency and wastage is removed from every business activity or function - including those that are not directly related to production

An Evaluation of TQM

Advantages | Disadvantages |

|---|---|

|

|

The Benefits of Lean Production & TQM

Implementing lean production and TQM can have a positive impact on various aspects of a business

It can lead to higher profits as a result of greater efficiency, less waste and lower costs

Fewer errors can lead to improved customer satisfaction and greater customer loyalty

Positive Impacts of Lean Production and TQM

Benefit | Explanation |

|---|---|

Waste reduction |

|

Streamlined processes |

|

Improved quality |

|

Employee empowerment |

|

Environmental Impact |

|

However, successful implementation of lean production is likely to require a cultural shift and ongoing efforts to sustain improvements

Commitment to careful recruitment, training and engagement of employees

'Getting it right first time' should be at the heart of all processes

It also needs strong relationships with suppliers

Defect-free components must be delivered on-time, in the right quantities

Trust needs to be developed with a small number of suppliers, emphasising quality rather than cost alone

Examiner Tips and Tricks

When developing a longer response that requires a justified decision, make sure that you consider the advantages and disadvantages of both options

This analysis should be wide ranging - that is, you should consider the impact on a variety of business functions, stakeholders, aims and objectives. Try to avoid focusing too much on financial aspects - though these should be covered.

National & international Quality Standards

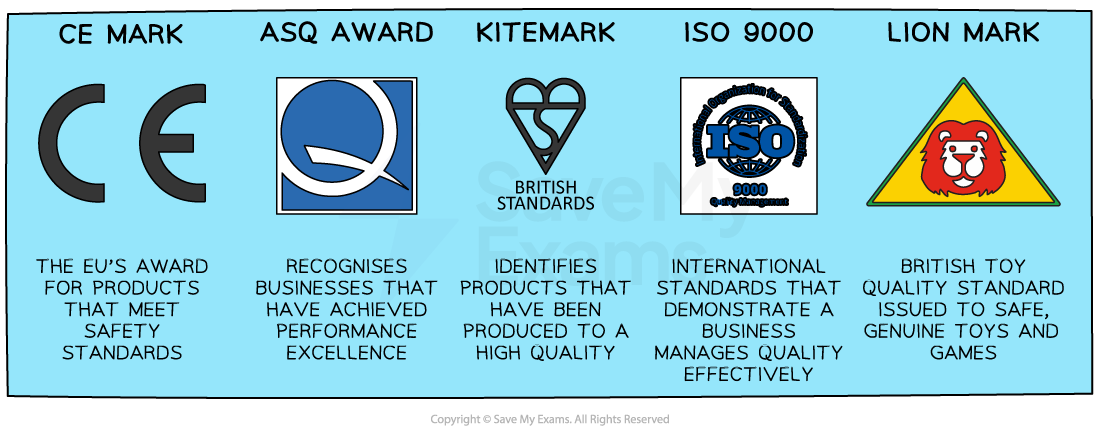

Quality standards include national and international benchmarks that demonstrate a businesses commitment to quality

They are administered by independent bodies that carry out stringent tests to ensure standards are met or exceeded

Businesses awarded these standards are revisited regularly to ensure that standards are maintained

Diagram with a Selection of Quality Standard Accreditations

The Importance of Quality Standards

Achieving accreditation reassures customers of their commitment to quality

Accreditation also provides a range of further benefits

Having quality accreditation can set a business apart from competitors

Obtaining quality accreditation can allow a business to enter these markets

They reduce the risk of legal issues and penalties

Examiner Tips and Tricks

You will not need to write about specific quality standards - it is enough to demonstrate an understanding of the types of protection they provide to consumers

You've read 0 of your 5 free revision notes this week

Unlock more, it's free!

Did this page help you?