Reorganising Production (DP IB Business Management) : Revision Note

Outsourcing & Subcontracting

Outsourcing is the process where a business delegates specific business activities (IT, customer support, HR etc) to external service providers

Businesses choose to outsource these functions to reduce costs, access specialised expertise, or focus on core competencies

Subcontracting occurs when specific parts of a larger project or contract are assigned to third-parties

The business remains responsible for the overall project or contract but certain components or tasks are delegated to other companies/individuals with specialised skills

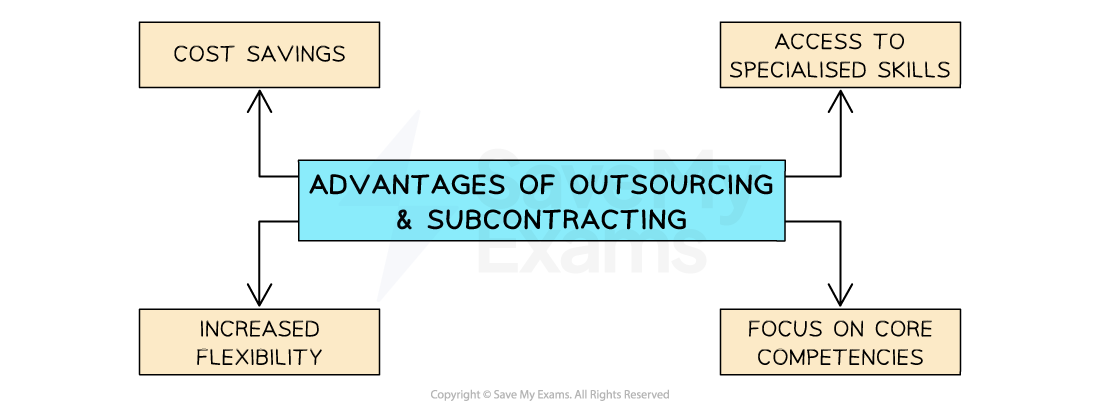

Diagram: advantages of outsourcing and subcontracting

Cost savings

Businesses can often reduce expenses associated with operations such as hiring and training employees, maintaining infrastructure and managing IT systems

Access to specialised skills

External specialists have resources that the business lacks internally which allows it to benefit from the knowledge and experience of industry specialists as and when required

Increased flexibility

They can provide greater flexibility to scale their operations up or down based on demand fluctuations which is particularly valuable in industries with seasonal or unpredictable demand

Focus on core competencies

Businesses can concentrate their resources and efforts on their core competencies where they can add value

Limitations of outsourcing and subcontracting

Quality control

Using external providers makes it harder to ensure consistent quality and adherence to company standards

Loss of control

Handing direct control over those activities to others outside of the business may be risky. Companies must carefully select reliable partners and establish clear contractual terms to protect their interests

Data security and confidentiality

Sharing sensitive information outside of the business introduces potential risks to data security and confidentiality

Communication and cultural differences

Using global providers may result in language barriers or problems with time zone differences. Cultural differences may present communication challenges

Offshoring

Offshoring occurs when a business sets up operations in another country to carry out certain business processes so as to:

Take advantage of lower labour costs

Gain access to specialised skills

Expand into new markets

Common examples of offshoring practices include call centres in foreign countries, software development teams or manufacturing plants established in countries with cheaper labour

Evaluation of Offshoring

Advantages | Disadvantages |

|---|---|

|

|

Insourcing

Insourcing is where a business assigns tasks to individuals within the organisation which were previously outsourced

There are several reasons why businesses may choose to insource certain activities

Diagram: reasons for insourcing

Cost control

Insourcing can be a cost-saving strategy as it eliminates the need to pay external specialists

Quality control

A business retains direct control over the quality of work being produced and may find it easier to establish their own standards

Flexibility

It provides the business with greater flexibility to respond to changing business needs, so can adjust workflows and adapt to new challenges

Knowledge and skill retention

Businesses can develop specialised skills within their own workforce, which can also reduce the risk of intellectual property breaches

Reshoring

Reshoring occurs when a business brings back its production activities to its home country from abroad

It involves reversing the previous decision to offshore or outsource those activities to another country

There are several reasons why a company may choose to reshore its operations

Diagram: reasons to reshore

Cost considerations

The initial cost advantages of offshoring may reduce due to factors such as rising labour or transportation costs in the foreign country

Quality control

By reshoring, companies can have better control over the manufacturing processes and ensure higher quality control standards, which may lead to improved customer satisfaction

Intellectual property protection

By bringing manufacturing back to their home country, they can reduce the risk of intellectual property theft

Supply chain resilience

The COVID-19 pandemic highlighted the vulnerabilities of global supply chains when disruptions in transportation, logistics and international trade led to delays and shortages of critical goods

Reshoring reduces dependence on foreign suppliers

Market proximity

Can allow companies to be closer to their target markets, which can lead to faster delivery times, reduced transportation costs and improved responsiveness to customer demands

You've read 0 of your 5 free revision notes this week

Sign up now. It’s free!

Did this page help you?