The Purpose of Operations Management (DP IB Business Management) : Revision Note

What is Operations Management?

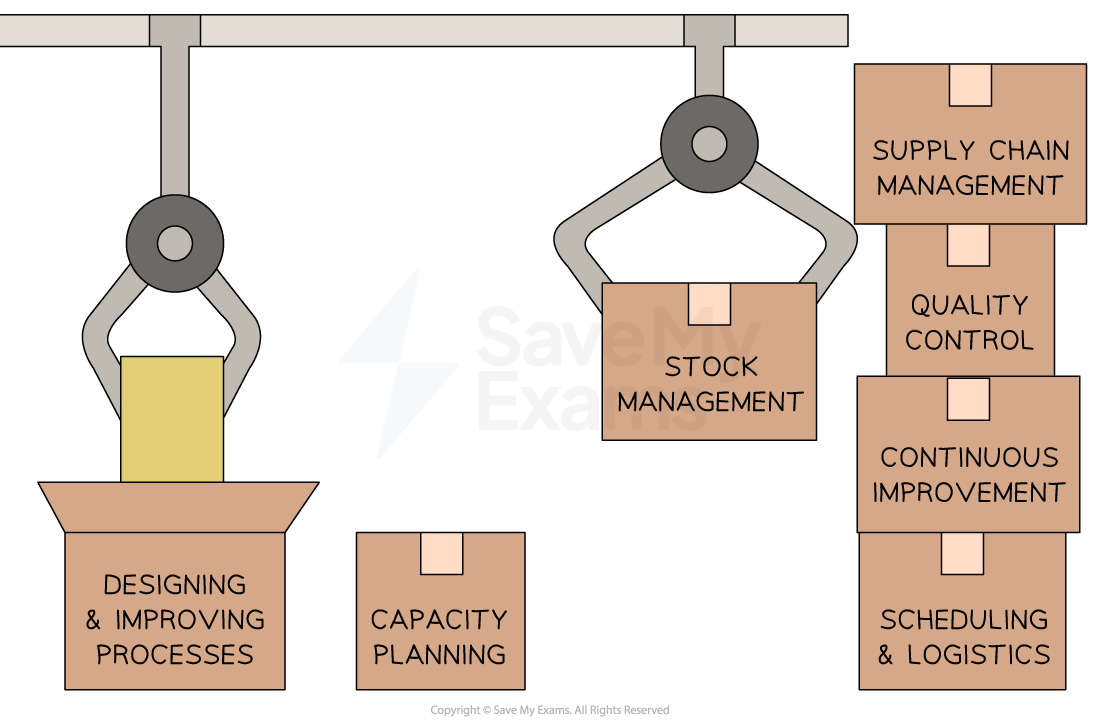

Operations management focuses on designing, controlling and improving the processes used in the production of goods and services

It involves overseeing the entire production process, from acquiring raw materials to delivering the final product/service to customers

The goal of operations management is to ensure that the production process is efficient, cost-effective and meets the desired quality standards

It involves making decisions related to production planning, stock management, resource allocation, scheduling and quality control

Diagram: operations management tasks

1. Designing and improving processes

Operations managers analyse existing processes and find ways to optimise them

They may use tools and techniques such as process mapping and lean production to identify inefficiencies and eliminate waste

2. Capacity planning

Operations managers determine the production capacity required to meet customer demand

They analyse historical data and market forecasts to ensure that the production resources are adequate to fulfil orders in a timely manner

3. Stock management

Operations managers are responsible for managing the stock levels of raw materials, work-in-progress and finished goods

They aim to minimise costs while ensuring that enough stock is available to meet customer demand and allow the production process to continue without running out of resources

4. Supply chain management

Operations managers work closely with suppliers to ensure the timely delivery of raw materials and components

They establish relationships with suppliers, negotiate contracts and monitor supplier performance to ensure a reliable supply chain

5. Quality control

Operations managers implement quality control measures to ensure that the products/services meet the required quality standards

They develop and enforce quality assurance processes, conduct inspections and address any quality issues that arise

6. Continuous improvement

Operations managers strive for ongoing improvement in processes, productivity and efficiency

They identify opportunities for innovation, implement new technologies or techniques and encourage a culture of continuous improvement (Kaizen) among employees

7. Scheduling and logistics

Operations managers develop production schedules and coordinate the flow of materials, equipment and labour to ensure smooth operations

Operations & the Production of Goods/Services

Operations management does not only focus on the production of tangible goods/services in the secondary sector

It is equally applicable in the primary, tertiary and quaternary sectors

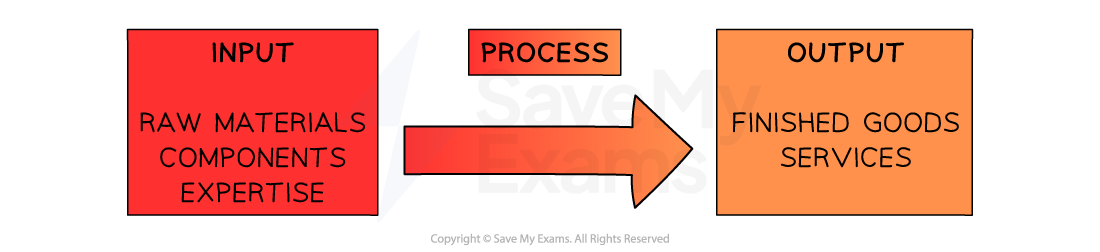

The input-output model is a simple explanation of the operations process

Diagram: the input-output model

Examples of the Input-Output Model in Different Sectors

Sector & Example | Inputs | Process | Outputs |

|---|---|---|---|

Primary (Fishing) |

|

|

|

Secondary (Car manufacture) |

|

|

|

Tertiary (Restaurant) |

|

|

|

Quaternary (Business consultancy) |

|

|

|

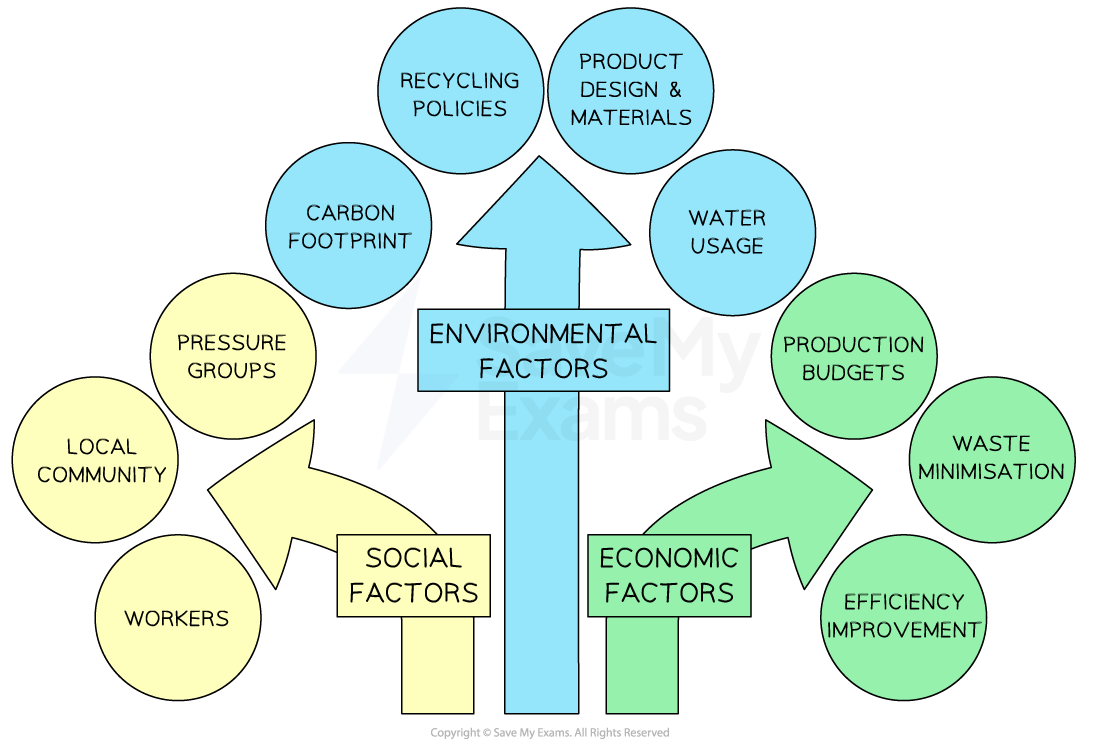

Operations & Sustainability

Sustainable operations management involves integrating sustainability practices into all aspects of the operations management process, from sourcing materials to delivering products

There are three elements to sustainable operations management

Diagram: sustainable operations management

There are a range of ways to improve sustainability in operations management

Examples of Sustainability Practices in Operations Management

Method | Explanation | Example |

|---|---|---|

Green Supply Chain Management |

|

|

Energy Efficiency |

|

|

Waste Reduction and Recycling |

|

|

Promoting fair labour practices |

|

|

You've read 0 of your 5 free revision notes this week

Sign up now. It’s free!

Did this page help you?