Stress-Strain Graphs (OCR A Level Physics) : Revision Note

Stress-Strain Graphs

Stress-strain curves give an indication of the properties of materials such as

Whether they are brittle, ductile or polymeric

Up to what stress and strain they obey Hooke's Law

Whether they exhibit elastic and/or plastic behaviour

The value of their Young Modulus

Each material has a unique stress-strain curve

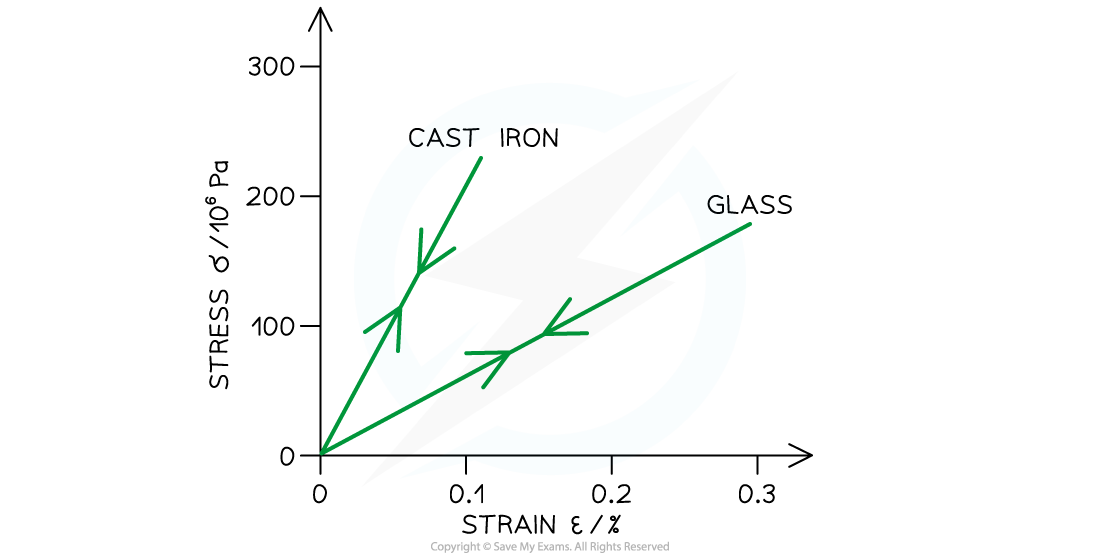

Brittle

A brittle material is defined asA material that fractures before plastic

deformation

For a brittle material:

Elastic behaviour is shown until the breakpoint where the material snaps

There is no plastic deformation, and the loading and unloading curves are the same

Brittle materials include: glass, ceramic

The stress-strain graph for a brittle material

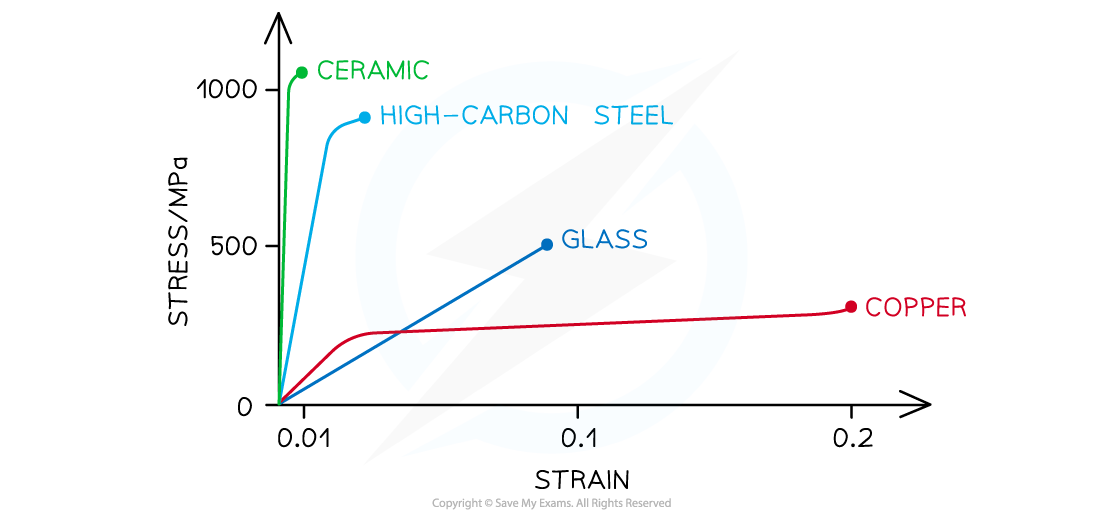

Ductile

A ductile material is defined as

A material that can withstand large plastic deformation without breaking

For a ductile material:

They generally experience elastic deformation up until their elastic limit

After this, they then undergo plastic deformation before reaching their ultimate tensile stress and breakpoint

For this reason, they can be easily hammered into thin sheets or drawn into long wires

Ductile materials include: copper

The stress-strain graph for a ductile material

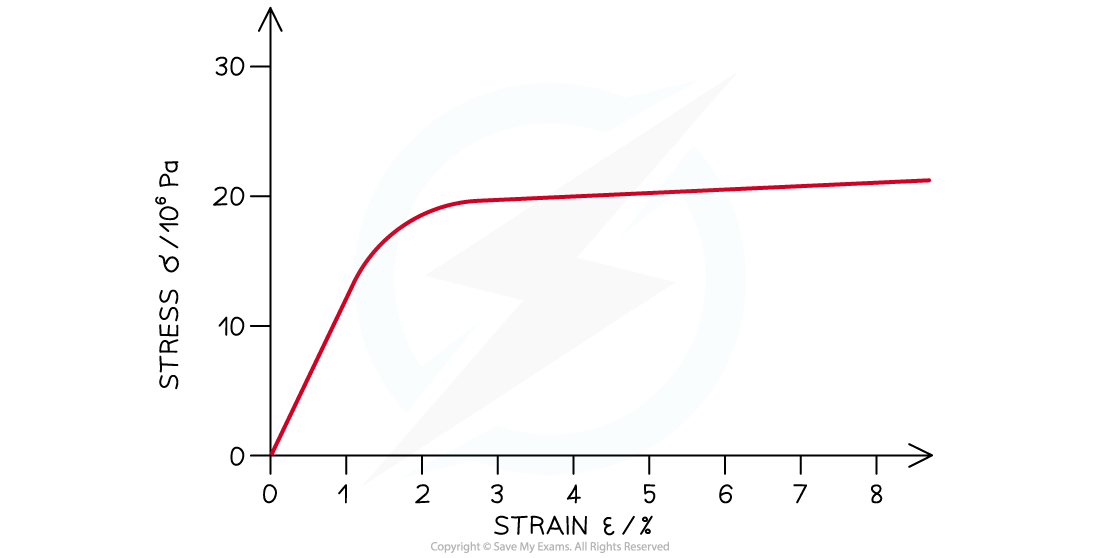

Polymeric

A polymeric material is defined as:

A material made up of long, repeating chains of molecules

For a polymeric material:

They can endure a lot of tensile stress before breaking

There is no plastic deformation, but the unloading curve is different to the loading curve, as some energy has been lost as thermal energy

Polymeric materials include: rubber, polythene

The stress-strain graph for a polymeric material

Stress-strain graph for different materials up to their breaking stress

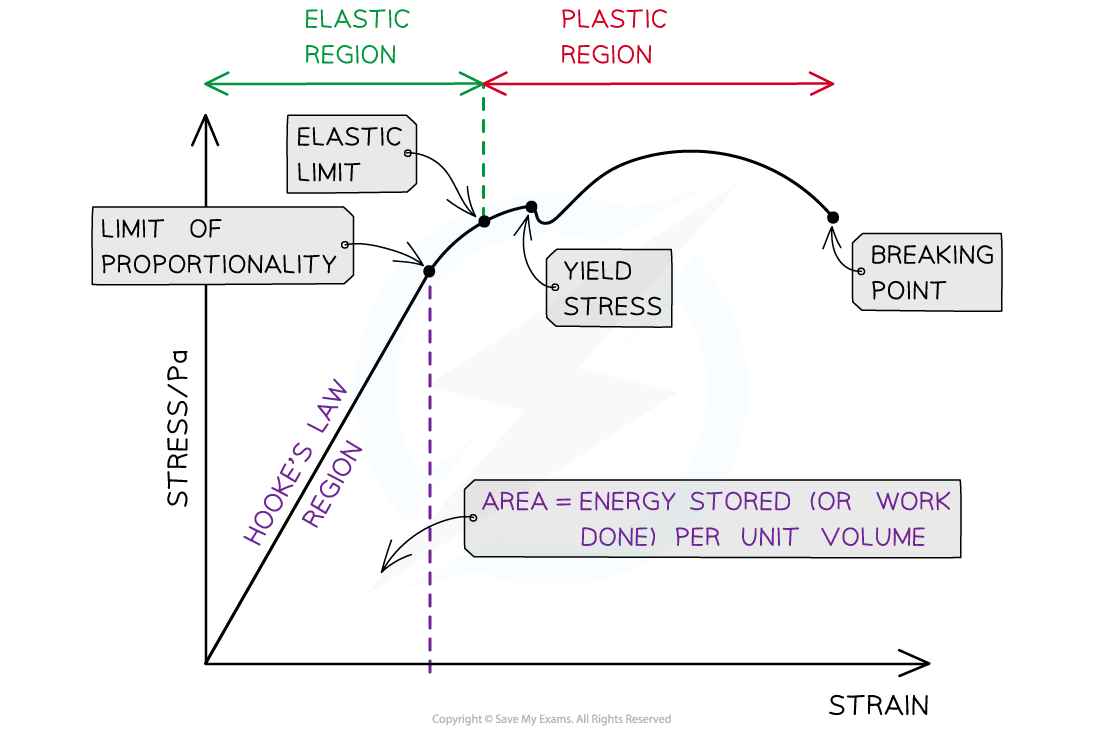

There are important points on the stress-strain graph, some are similar to the force-extension graph

The important points shown on a stress-strain graph

The key points that are unique to the stress-strain graph are:

The elastic strain energy stored per unit volume is the area under the Hooke's Law (straight line) region of the graph

Yield Stress:

The force per unit area at which the material extends plastically for a small increase in stress

Breaking point:

The stress at this point is the breaking stress

This is the maximum stress a material can stand before it fractures

Elastic region:

The region of the graph up until the elastic limit

In this region, the material will return to its original shape when the applied force is removed

Plastic region:

The region of the graph after the elastic limit

In this region, the material has deformed permanently and will not return to its original shape when the applied force is removed

Worked Example

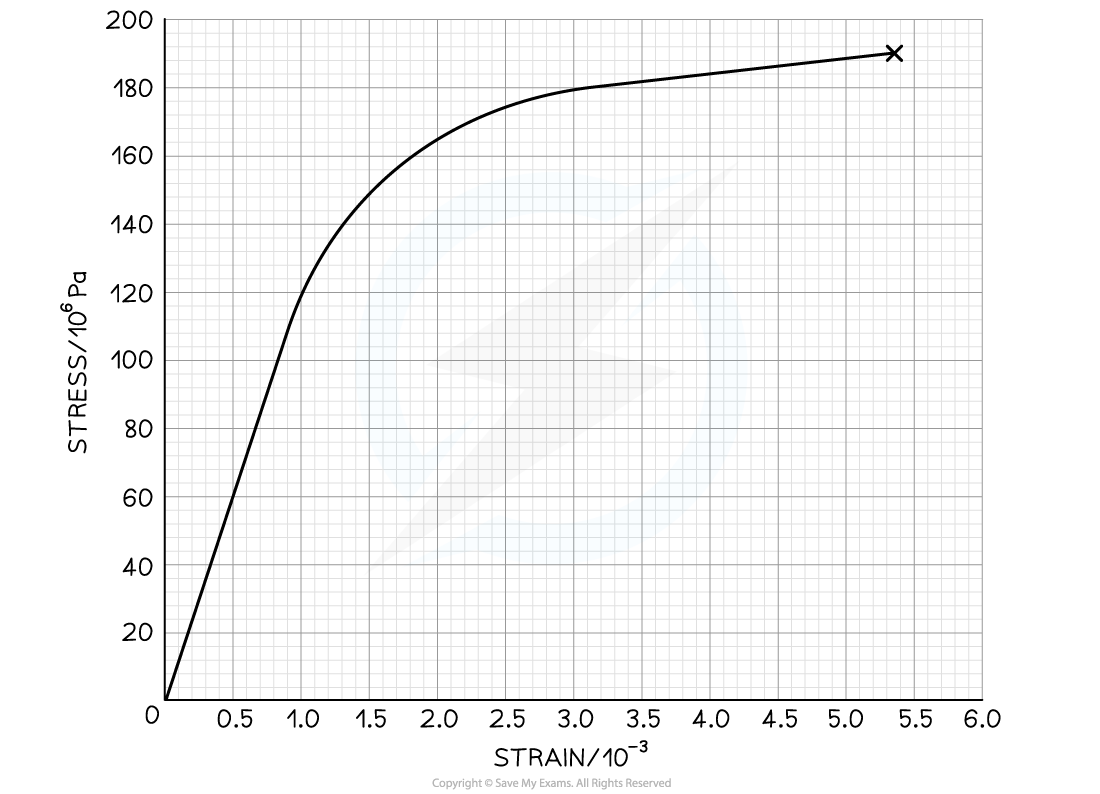

The graph below shows a stress-strain curve for a copper wire.

From the graph, state the value of:

(a) The breaking stress

(b) The stress at which plastic deformation begins

Answer:

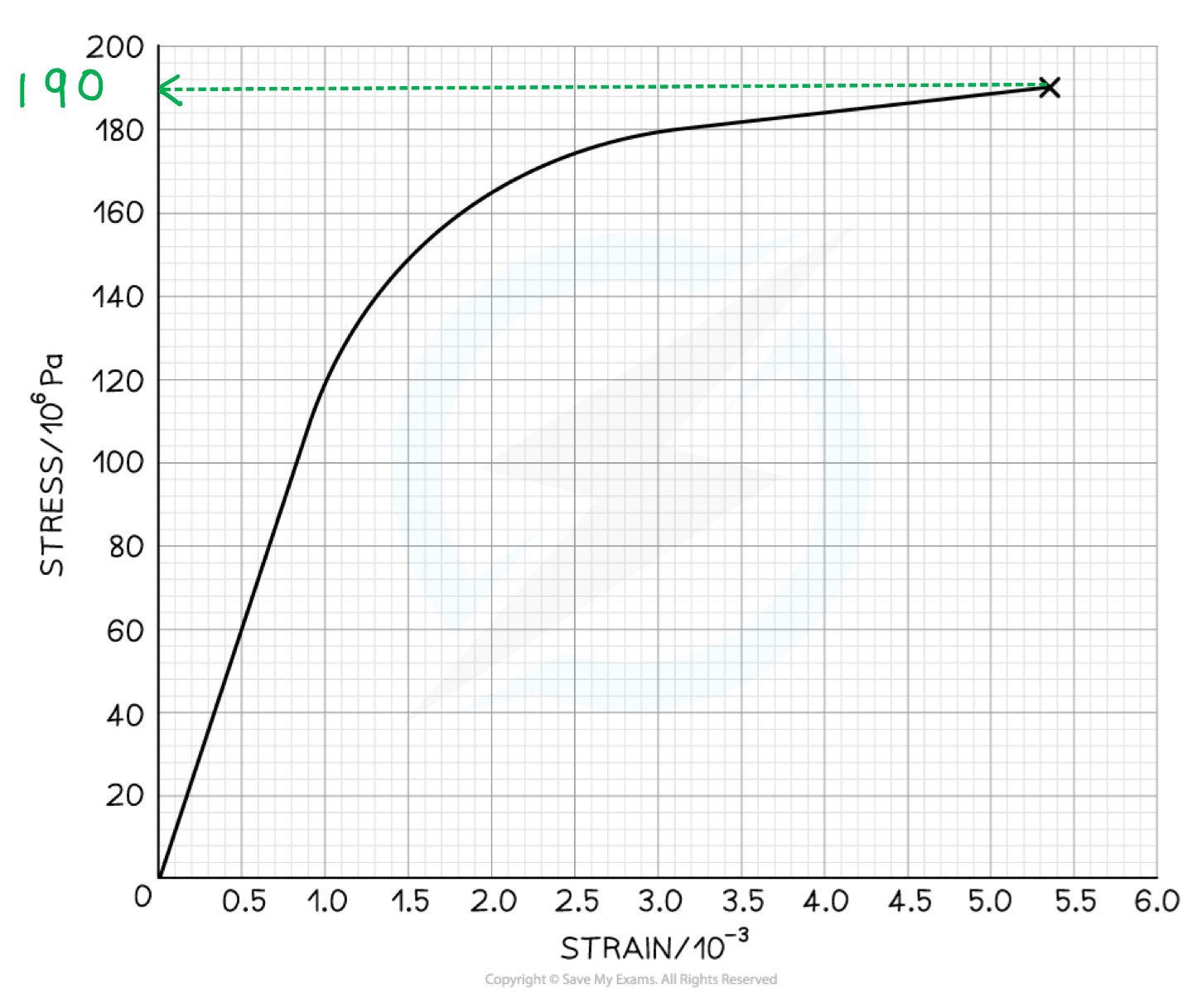

Part (a)

Step 1: Define breaking stress

The breaking stress is the maximum stress a material can stand before it fractures. This is the stress at the final point on the graph

Step 2: Determine breaking stress from the graph

Draw a line to the y axis at the point of fracture

The breaking stress is 190 MPa

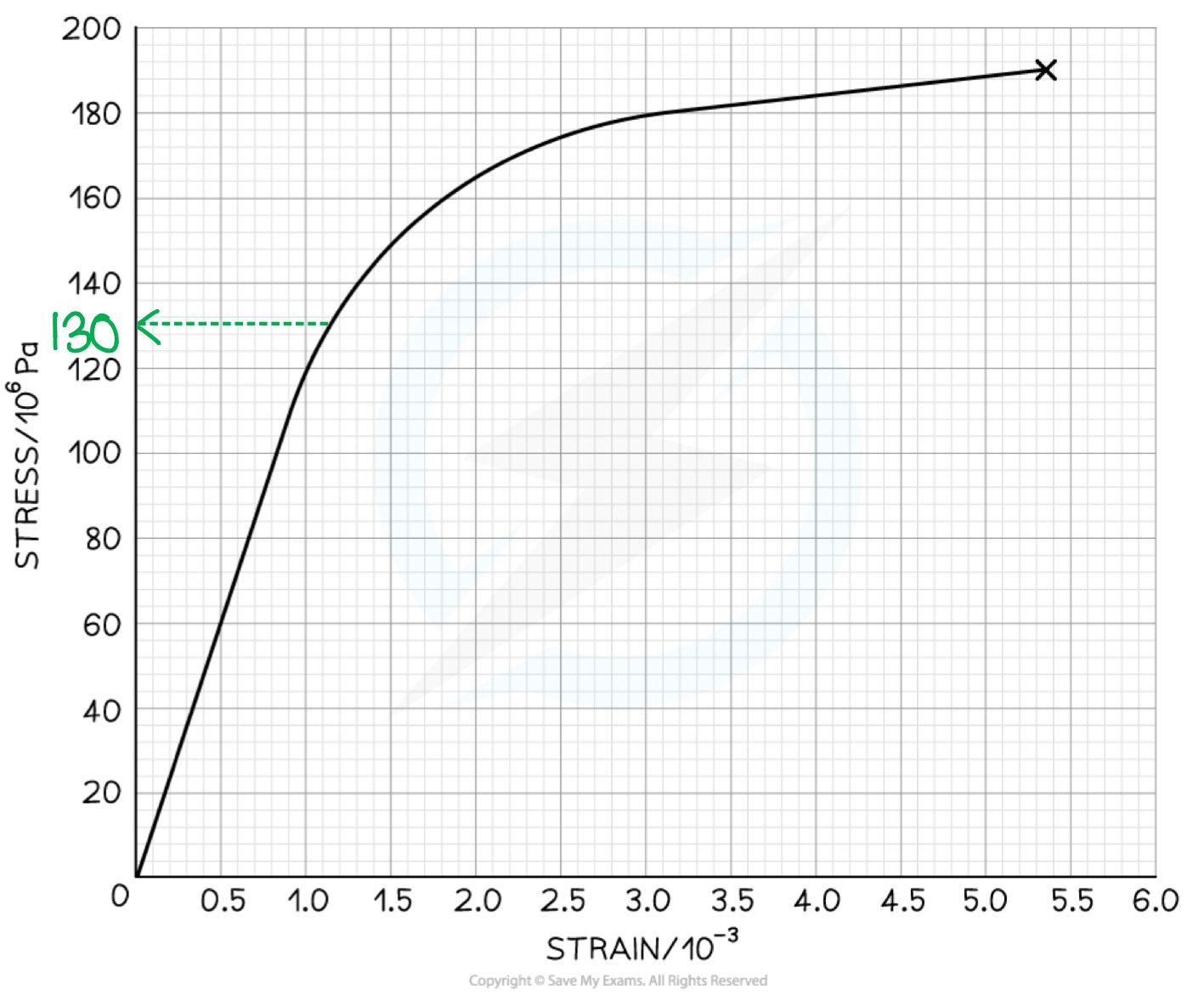

Part (b)

Step 1: Define plastic deformation

Plastic deformation is when the material is deformed permanently and will not return to its original shape once the applied force is removed

This is shown on the graph where it is curved

Step 2: Determine the stress of where plastic deformation beings on the graph

Draw a line to the y axis at the point where the graph starts to curve

Plastic deformation begins at a stress of 130 MPa

You've read 0 of your 5 free revision notes this week

Sign up now. It’s free!

Did this page help you?