The Young Modulus (Cambridge (CIE) A Level Physics) : Revision Note

Stress, strain & the Young modulus

Stress

Tensile stress is the applied force per unit cross sectional area of a material

Where:

σ is tensile stress in Pa

F is applied force in N

A is the cross-sectional area of the object in m2

The ultimate tensile stress is the maximum force per original cross-sectional area a wire is able to support at the point it breaks

Strain

Strain is the extension per unit length

Strain is the deformation of a solid due to stress in the form of elongation or contraction

Note that strain, ε , is a dimensionless unit because it is the ratio of lengths given by the equation

Where:

x is extension in metres (m)

L is the original length of the object, also in metres (m)

Young modulus

The Young modulus, E , is a measure of the ability of a material to withstand changes in length when a load is added

Young modulus is a measure of how stiff or elastic a material is

The Young Modulus is defined as the ratio of stress and strain and is given by the equation

Where:

E is Young modulus where its unit are the same as stress: Pa (since strain is unitless)

For a material demonstrating elastic behaviour, stress and strain, like force and extension, are also directly proportional to one another

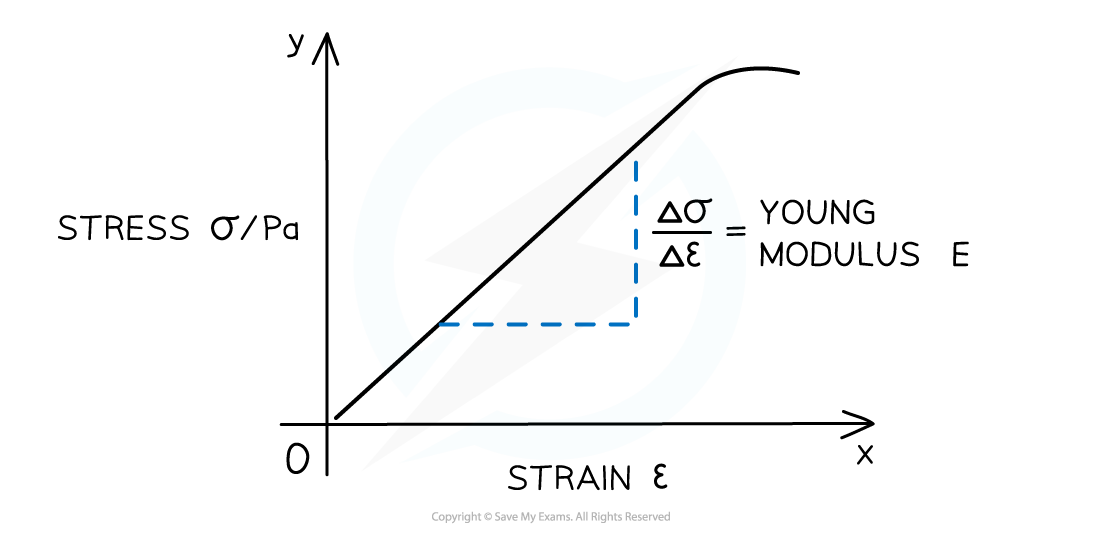

The directly proportional nature of the stress-strain relationship can be shown by drawing a stress-strain graph

The gradient of the linear section of a stress-strain graph is the Young modulus

Stress-strain graph

A stress-strain graph is a straight line with its gradient equal to Young modulus

Worked Example

A metal wire that is supported vertically from a fixed point has a load of 92 N applied to the lower end.

The wire has a cross-sectional area of 0.04 mm2 and obeys Hooke’s law.

The length of the wire increases by 0.50%. What is the Young modulus of the metal wire?

A. 4.6 × 107Pa

B. 4.6 × 1012 Pa

C. 4.6 × 109 Pa

D. 4.6 × 1011 Pa

Answer: D

Step 1: List the known quantities:

Load force, F = 92 N

Cross-sectional area, A = 0.04 mm2

Extension is 0.50% of the original length

Step 2: Determine the stress:

Convert the area to m2

Substitute this into the stress equation

Step 3: Determine strain:

Strain is defined as the extension per unit length

If extension is 0.50% of length, then strain is simply this value as a decimal number

Step 4: Calculate the Young modulus:

Substitute these values into the equation

Examiner Tips and Tricks

To remember whether stress or strain comes first in the Young modulus equation, try thinking of the phrase ‘When you’re stressed, you show the strain’ i.e. .

Young's modulus experiment

Equipment

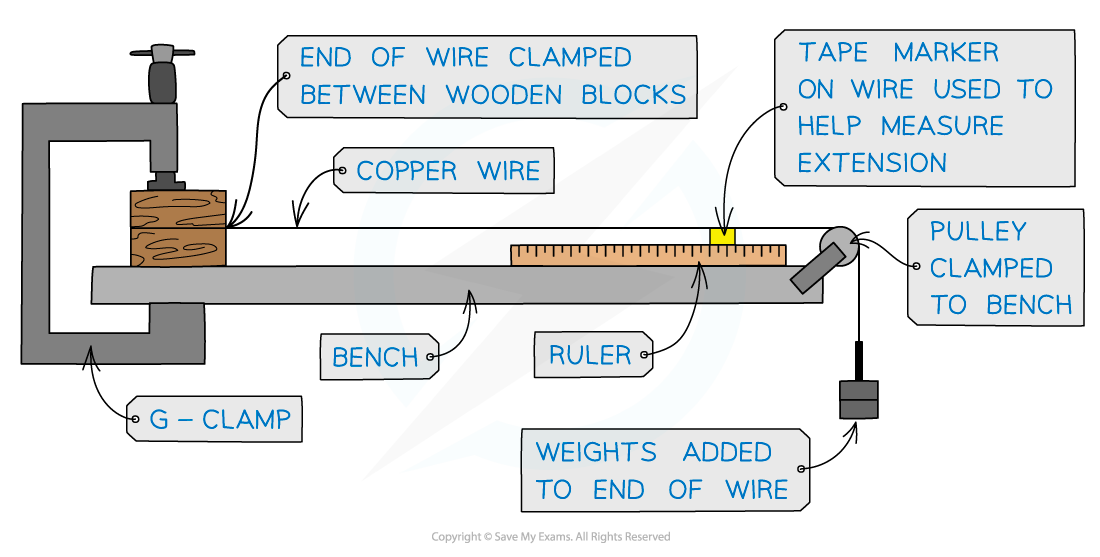

To measure the Young modulus of a metal in the form of a wire requires the wire to be clamped over a pulley as shown in the diagram below

Experimental equipment to determine the Young modulus

As the wire stretches, the tape marker moves along the ruler, showing the extension of the wire. This is based on the assumption that the wire stretches the same amount at all points along its length.

A tape or reference marker is needed on the wire to accurately measure the extension with the applied load

The independent variable is the load

The dependent variable is the extension

Method

Measure the original length of the wire using a metre ruler and mark this reference point with tape

Measure the diameter of the wire with a micrometre screw gauge or digital callipers

Add the first mass and calculate the weight used to create the extension e.g. 300 g

Record the total length from the reference point on the metre ruler

Add more mass and record the new total length from the metre ruler

Subtract the original length from the new total length to obtain the extension

Improving experiment and reducing uncertainties

Reduce uncertainty of the cross-sectional area by measuring the diameter d in several places along the wire and then calculating an average

After each reading remove the load and check that the wire returns to its original shape after each reading

Take several readings with each loads and find the average extension

Use a Vernier scale to measure the extension of the wire

Measurements required to determine the Young modulus

1. Determine extension from final and initial readings

Example table of results

Mass / kg | Load / N | Initial length / mm | Final length / mm | Extension / × 10−3 m |

|---|---|---|---|---|

0.2 | 2.0 | 500 | 500.1 | 0.1 |

0.3 | 2.9 | 500.1 | 500.4 | 0.3 |

0.4 | 3.9 | 500.4 | 501.0 | 0.6 |

0.5 | 4.9 | 501.0 | 501.9 | 0.9 |

0.6 | 5.9 | 501.9 | 503.2 | 1.3 |

0.7 | 6.9 | 503.2 | 504.9 | 1.7 |

0.8 | 7.8 | 504.9 | 507.0 | 2.1 |

Table with additional data

QUANTITY / UNIT | SIZE |

|---|---|

Length L / m | 1.382 |

Diameter 1 / mm | 0.277 |

Diameter 2 / mm | 0.280 |

Diameter 3 / mm | 0.275 |

Average diameter / mm | 0.277 |

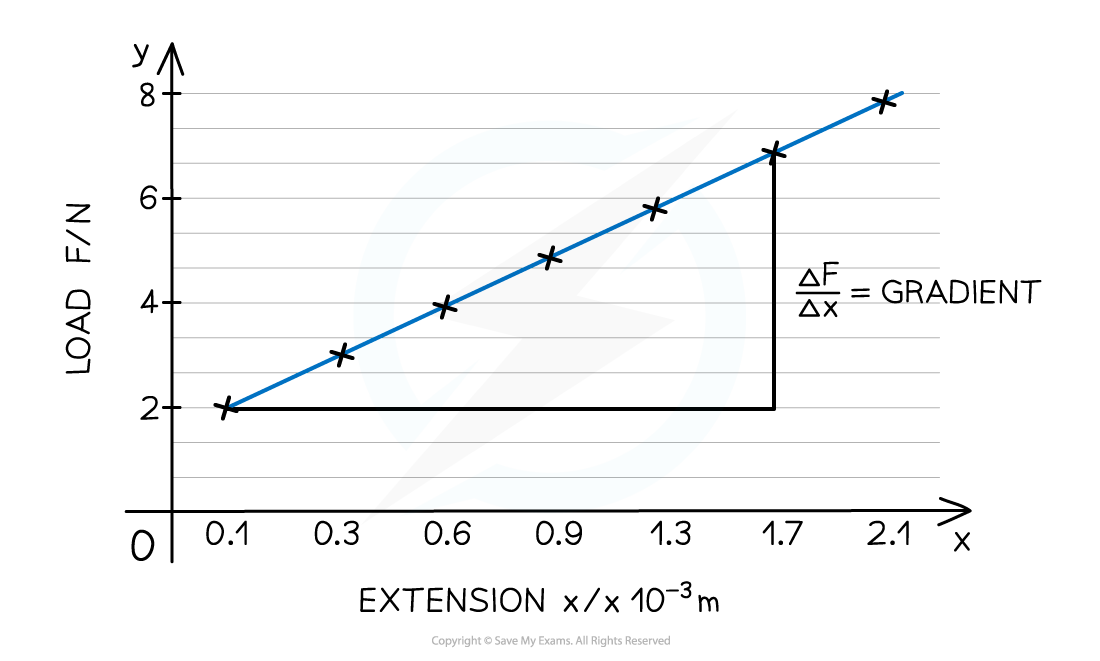

2. Plot a graph of force against extension and draw a line of best fit

3. Determine the gradient of the force-extension graph

Force-extension graph

This gradient is neither stress nor strain, but can be used to calculate Young's modulus

4. Calculate the cross-sectional area A of the wire from:

where d is the average diameter of the wire

5. Calculate the Young modulus from:

using the gradient of the force-extension graph, the initial length of the wire and it's average cross-sectional area

Examiner Tips and Tricks

Although every care should be taken to make the experiment as reliable as possible, you will be expected to suggest improvements in producing more accurate and reliable results (e.g. repeat readings and use a longer length of wire)

You've read 0 of your 5 free revision notes this week

Sign up now. It’s free!

Did this page help you?