Stress & Strain (AQA A Level Physics) : Revision Note

Tensile Stress & Strain

Opposite forces can deform an object

If the forces stretch the object, then they are tensile forces

Tensile forces lead to the two properties of materials known as tensile stress and tensile strain

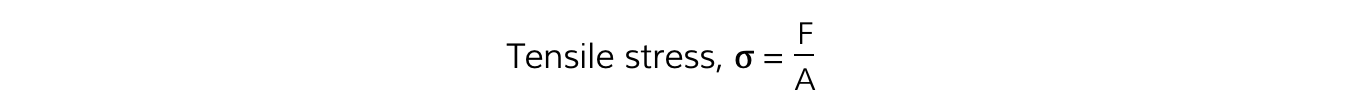

Tensile Stress

Tensile stress is defined as the force exerted per unit cross-sectional area of a material

Where:

σ = tensile stress (Pa)

F = force applied (N)

A = cross-sectional area (m2)

The ultimate tensile stress is the maximum force per original cross-sectional area a wire is able to support until it breaks

σ is the greek letter lower-case 'sigma'

σ has the units of pascals (Pa), which is the same units as pressure (also force ÷ area)

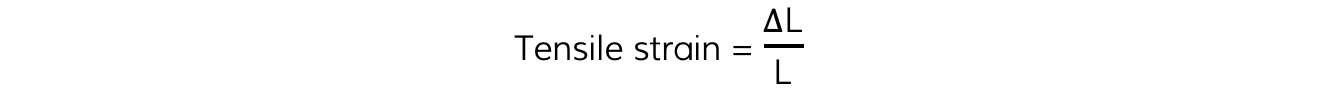

Tensile Strain

Strain is the extension per unit length

This is a deformation of a solid due to stress in the form of elongation or contraction

Where:

ΔL = extension (m)

L = original length (m)

The strain is a dimensionless unit because it’s the ratio of lengths

Sometimes strain might be written as a percentage

For example, extending a 0.1 m wire by 0.005 m would produce a strain of (0.005 ÷ 0.1) × 100 = 5 %

Worked Example

A brass wire of length 4.50 m and a radius of 0.2 mm is extended to a total length of 4.53 when a tensile force of 50 N is applied.

Calculate for the brass wire:

(i) The tensile stress

(ii) The tensile strain

Answer:

(i) Calculate the tensile stress

Step 1: Write down the tensile stress equation

Tensile stress = Force ÷ Cross-sectional area

Step 2: Calculate the cross-sectional area, A of the wire

A wire has a circular cross-sectional area = πr2

Area = π × (0.2 × 10-3)2 =1.2566 × 10-7 m2

Step 3: Substitute values in the tensile stress equation

Tensile stress = 50 ÷ (1.2566 × 10-7) = 397.899 × 106 Pa = 400 MPa

(ii) Calculate the tensile strain

Step 1: Write down the tensile strain equation

Tensile strain = Extension ÷ Original length

Step 2: Determine the extension

The extension is total length – the original length

Extension = 4.53 – 4.50 = 0.03 m

Step 3: Substitute values in the tensile strain equation

Tensile strain = 0.03 ÷ 4.50 = 6.7 × 10-3

Examiner Tips and Tricks

Since strain is a ratio, the extension and original length do not have to be calculated in metres. As long as they both have the same units, the strain will be correct

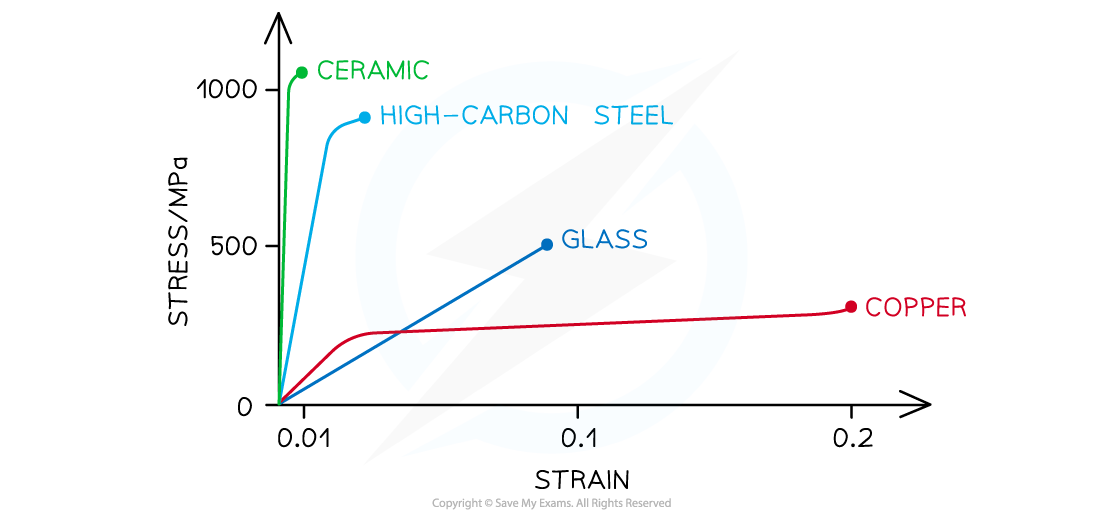

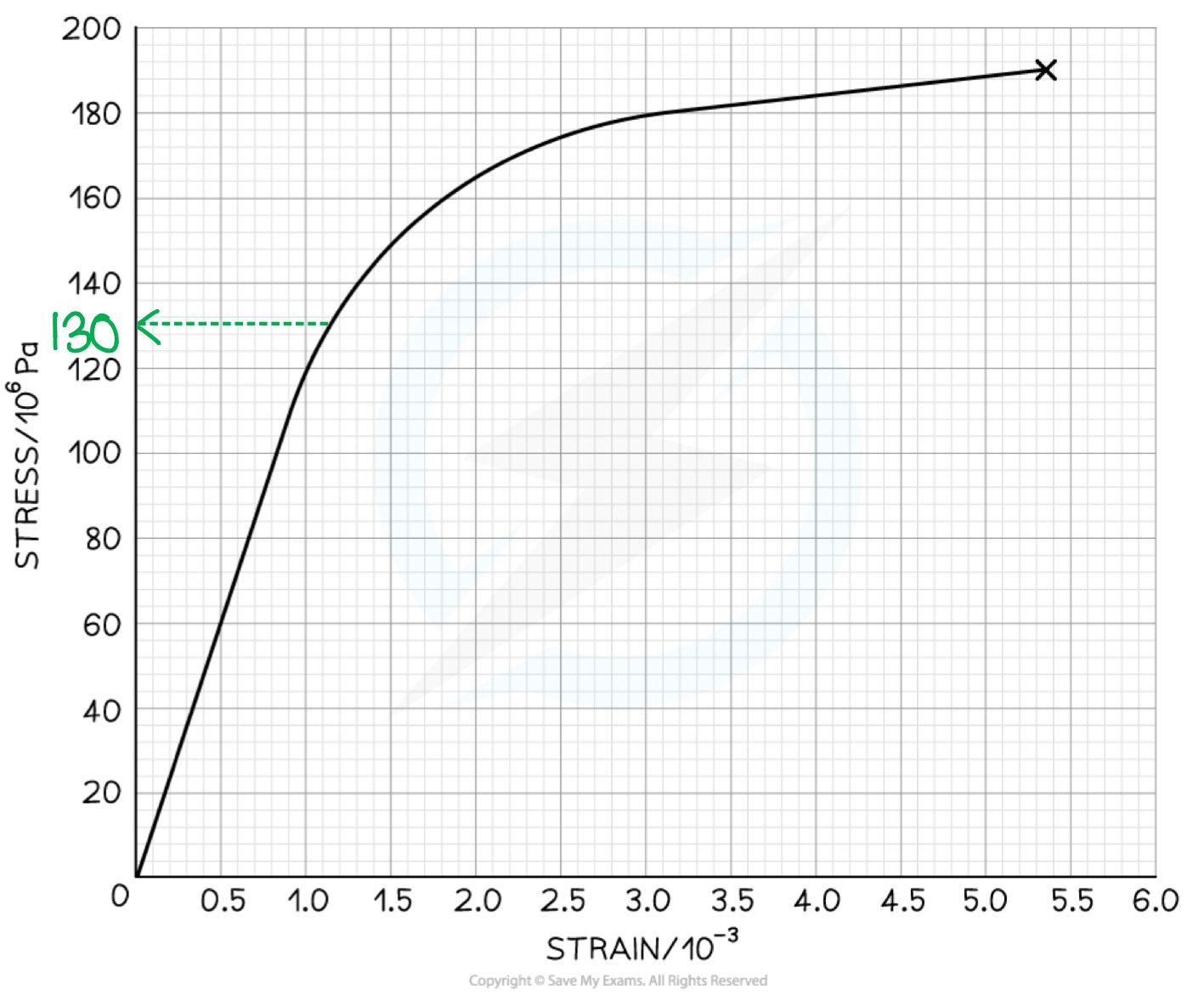

Stress-Strain Curves

Stress-strain curves describe the properties of materials such as whether they are brittle, ductile and up to what stress and strain they obey Hooke's Law and have elastic and / or plastic behaviour

Each material will have a unique stress-strain curve

Stress-strain graph for different materials up to their breaking stress

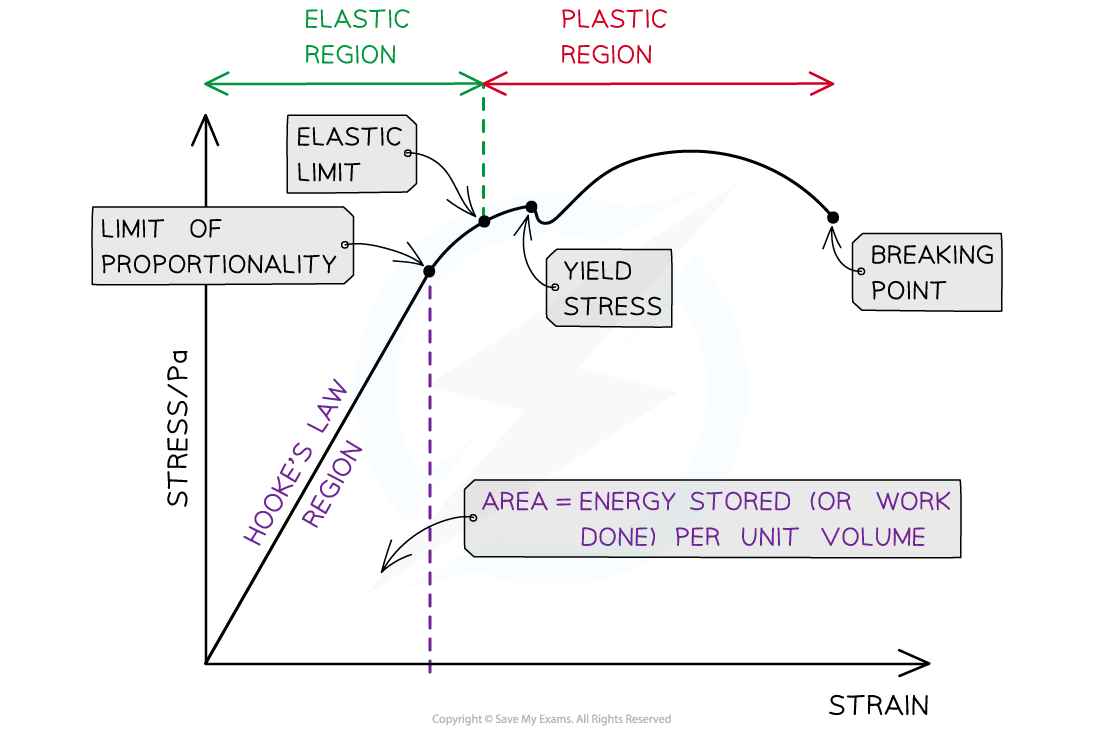

There are important points on the stress-strain graph, some are similar to the force-extension graph

The important points shown on a stress-strain graph

The key points that are unique to the stress-strain graph are:

Yield Stress: The force per unit area at which the material extends plastically for no / a small increase in stress

The elastic strain energy stored per unit volume is the area under the Hooke's Law (straight line) region of the graph

Breaking point: The stress at this point is the breaking stress. This is the maximum stress a material can stand before it fractures

Elastic region: The region of the graph up till the elastic limit. In this region, the material will return to its original shape when the applied force is removed

Plastic region: The region of the graph after the elastic limit. In this region, the material has deformed permanently and will not return to its original shape when the applied force is removed

Worked Example

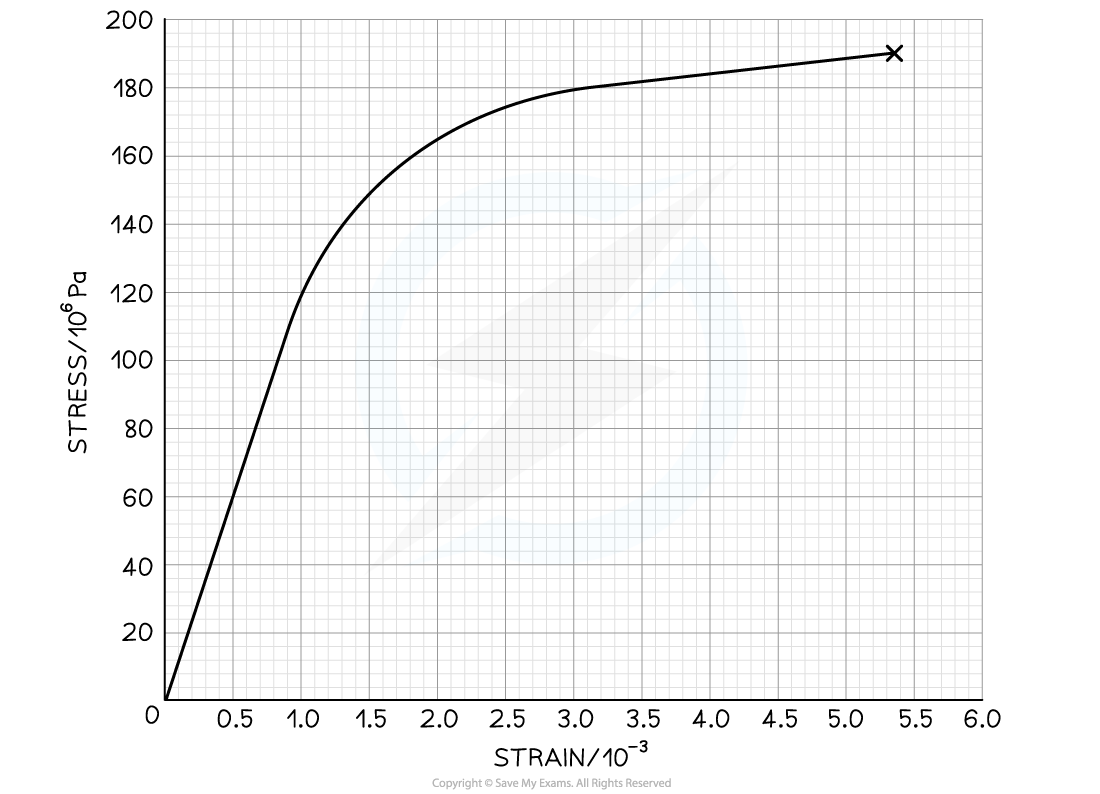

The graph below shows a stress-strain curve for a copper wire.

From the graph state the value of:

(i) The breaking stress

(ii) The stress at which plastic deformation begins

Answer:

(i) The breaking stress

Step 1: Define breaking stress

The breaking stress is the maximum stress a material can stand before it fractures. This is the stress at the final point on the graph

Step 2: Determine breaking stress from the graph

Draw a line to the y axis at the point of fracture

The breaking stress is 190 MPa

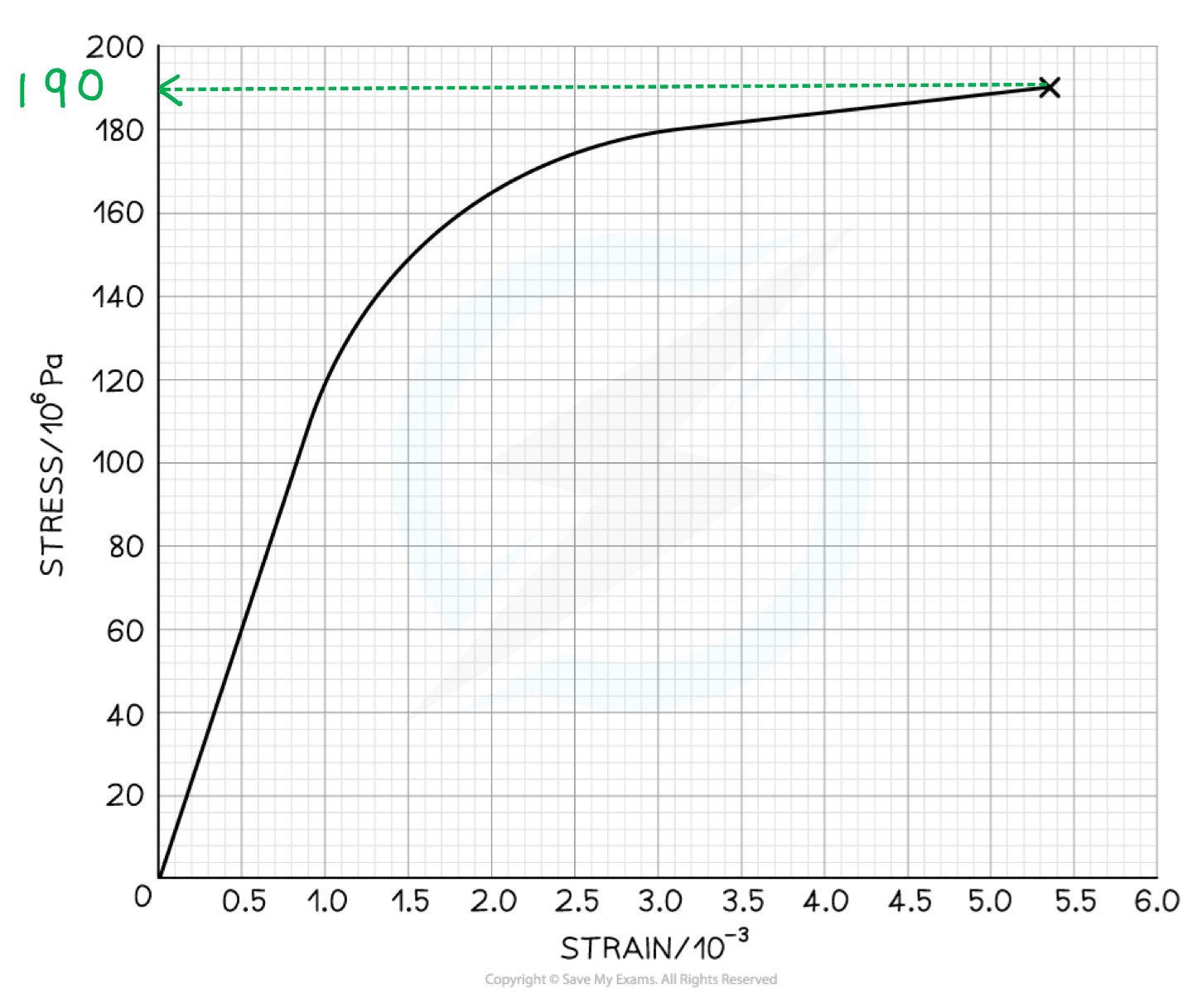

(ii) The stress at which plastic deformation begins

Step 1: Define plastic formation

Plastic deformation is when the material is deformed permanently and will not return to its original shape once the applied force is removed. This is shown on the graph where it is curved

Step 2: Determine the stress of where plastic deformation beings on the graph

Draw a line to the y axis at the point where the graph starts to curve

Plastic deformation begins at a stress of 130 MPa

Examiner Tips and Tricks

For graph questions where the reading is subjective, the mark scheme generally allows for an acceptable range. In the above graph, an acceptable range for the graph to start curving is 120 MPa - 135 MPa.

You've read 1 of your 5 free revision notes this week

Sign up now. It’s free!

Did this page help you?