Quality Management (Edexcel A Level Business) : Revision Note

Quality management methods

Quality considers the characteristics and features of a product that satisfy the needs of customers

Businesses need to maintain a level of quality that continues to attract and retain customers

There are a number of approaches to managing quality in the production process

Methods of quality management

Method | Explanation |

|---|---|

Quality control |

|

Quality assurance |

|

Quality circles |

|

Total quality management (TQM) |

|

Continuous improvement (Kaizen)

Kaizen involves a business taking continuous steps to improve productivity through the elimination of all types of waste in the production process

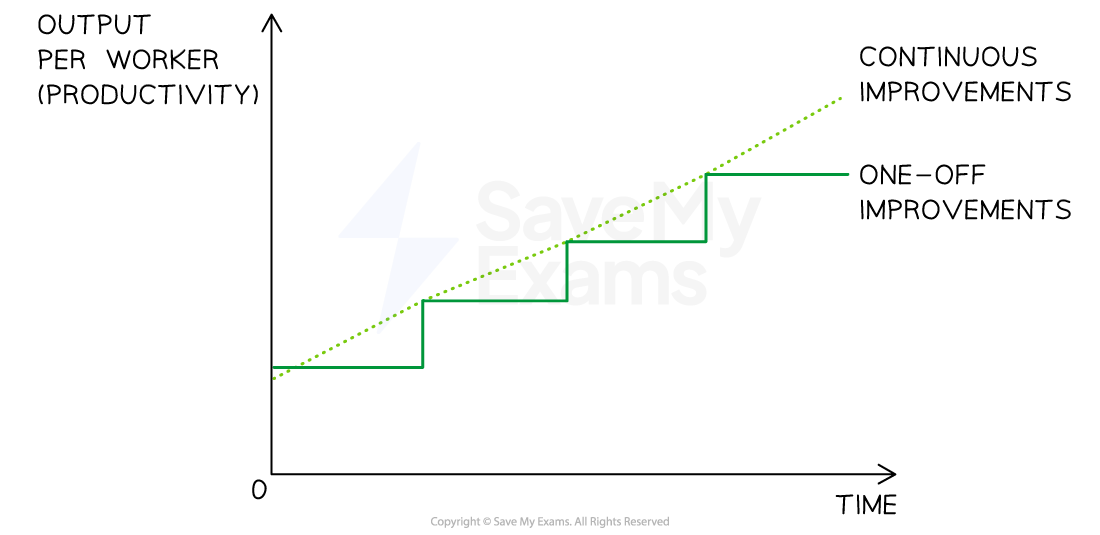

Changes are small and ongoing rather than significant one-off’s and are constantly reviewed to ensure that the desired positive impact on productivity is achieved

Comparison of kaizen and one-off improvements

Elements of Kaizen commonly include

Total Quality Management

Just in Time stock management

Teamwork and quality circles

Zero defects in manufacturing

High levels of automation

High levels of cooperation between workers and management

Kaizen requires a long-term management commitment to change

Competitive advantage from quality management

The quality of a businesses products can provide a competitive advantage

Unit costs are likely to be low if a business takes a preventative approach through the use of quality assurance or TQM

Low costs may allow a business to reduce its selling price to better compete with or undercut its rivals

Increased finance may be available to fund marketing activity to improve brand recognition and attract new customers

High levels of quality can be used in promotional activity and provide a unique selling point for businesses in competitive markets

Successfully developing a USP for quality can ease expansion into new markets as a result of the positive reputation it creates

You've read 0 of your 5 free revision notes this week

Sign up now. It’s free!

Did this page help you?