Production, Productivity & Efficiency (Edexcel A Level Business): Revision Note

Exam code: 9BS0

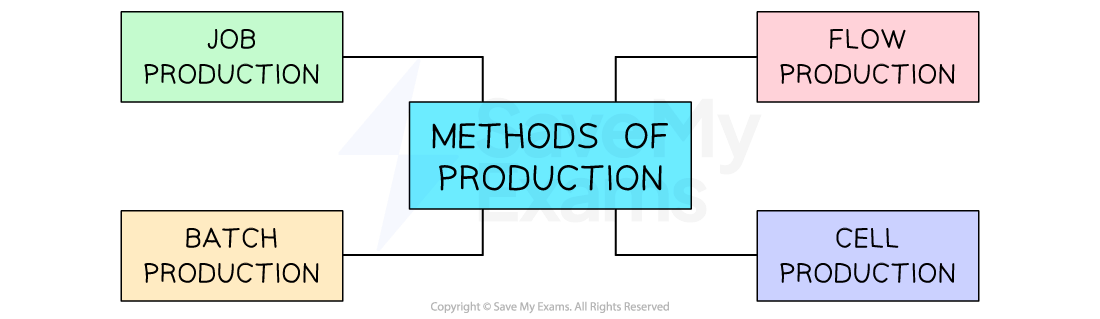

Methods of production

Production is the transformation of resources (e.g. raw materials, components and processes) into finished goods or services

Goods are physical products, such as bicycles and T-shirts

Services are non-physical items, such as hairdressing, tourism and manicures

Businesses can organise their production processes in a variety of ways

The main methods of production

The method of production used by a business will depend on a number of factors, including:

The level of output required to be produced

The nature of the product

Whether the product is standardised or customised

The level of automation used in production

Job production

Producing one item at a time, as ordered by the customer

Advantages

High-quality product

Motivated and highly skilled workers

Customised products can be produced

Disadvantages

Production is slow

Labour costs are high

Batch production

Groups of the same product are produced before moving on to a group of different products

Advantages

Workers can specialise

Production can take place as the previous batch starts running out

Disadvantages

Requires careful coordination to avoid shortages

Money is tied up in stock, as completed products need to be stored

Flow production

Continuous manufacturing of standardised products, usually on a production line

Advantages

Low unit costs due to economies of scale

Rapid production

Usually highly automated (capital-intensive)

Disadvantages

Customisation is difficult

Capital equipment can be expensive to purchase

Cell production

This involves workers being organised into multi-skilled teams, with each team responsible for a particular part of the production process

Advantages

Cell production is often more efficient than other methods, as workers share their skills and expertise

Motivation is usually high, as employees work as a team

Disadvantages

Requires extensive reorganisation of production processes

Teams' efficiency may be reduced by weaker workers

Worked Example

Blush Cosmetics uses batch production to make its range of soaps and bath bombs, with a variety of unique ingredients and scents. The business sells its products in its own high street store and online and has recently started supplying its products in small quantities to a chain of exclusive hotels.

Explain one likely reason why Blush Cosmetics chooses to use batch production. [4]

Step 1: Identify a reason for the business to use batch production

One reason for Blush Cosmetics to use batch production is that it allows groups of products with varied ingredients to be manufactured. [K]

Step 2: Include a reference to the business scenario

Blush Cosmetics sells a range of bath bombs and soaps that have different fragrances, colours and ingredients. [Ap]

Step 3: Develop the reason using a connective

Blush Cosmetics needs to produce significant levels of output to meet increasing demand and batch production, as well as to provide the opportunity to change ingredients between batches [An], which can allow quite large quantities to be produced for the company's high street and online stores [An].

Or:

Using batch production can allow Blush Cosmetics to produce smaller quantities of unique products for exclusive hotel customers [Ap], meeting their specific needs [An].

Examiner Tips and Tricks

Carefully consider the needs of the customers to whom a business sells when recommending a suitable method of production.

Where the selling price is a key driver of consumer demand, flow production (where unit costs are minimised) is likely to be very suitable.

Where demand is driven by quality or where customisation is required, job production or batch production is likely to be a better choice.

Calculating productivity

Productivity is the output per input (person or machine) per hour (e.g. an IKEA worker is able to produce two Poāng chairs per hour)

This is not production, which is the total amount of output produced in a time period (e.g. IKEA produced 300 Poāng chairs in February)

Labour productivity

The labour productivity of a business is a measure of the output per worker during a specified period of time

Labour productivity is calculated using the formula

Capital productivity

Capital productivity is a measure of the output of capital employed (e.g. machinery) during a specified period of time

Capital productivity is calculated using the formula

Worked Example

The table shows the number of pairs of luxury wool socks produced by Scotty Socks Ltd in 2021 and 2022.

Year | Units produced |

|---|---|

2021 | 46,000 |

2022 | 69,000 |

In 2021, Scotty Socks employed 50 staff. In 2022, the number of staff employed by the business increased by 20%.

Calculate the percentage change in labour productivity between 2021 and 2022.

[4]

Step 1: Calculate the labour productivity for 2021

[1]

Step 2: Calculate the labour productivity for 2022

[1]

Step 3: Calculate the percentage difference between the two years ([new−old] ÷ old)

[1]

Step 4: Identify whether the percentage difference is an increase or a decrease

25% increase [1]

Worked Example

Rolvo Ltd forecasts that by the end of the year, it will produce 250,800 units and that capital productivity will be 1,100 units per machine.

Calculate the number of machines Rolvo Ltd has in use.

Step 1: Divide the output by the capital productivity

Factors that influence productivity

The productivity within a business can often be improved

When productivity increases, business costs decrease

When business costs decrease, the firm can either pass on this decrease to consumers in the form of lower prices or maintain the selling prices and enjoy higher profit margins

Factors that influence productivity

Factor | Explanation |

|---|---|

Employee motivation |

|

Skills, education and training staff |

|

Business organisation and working practices |

|

Investment in capital equipment |

|

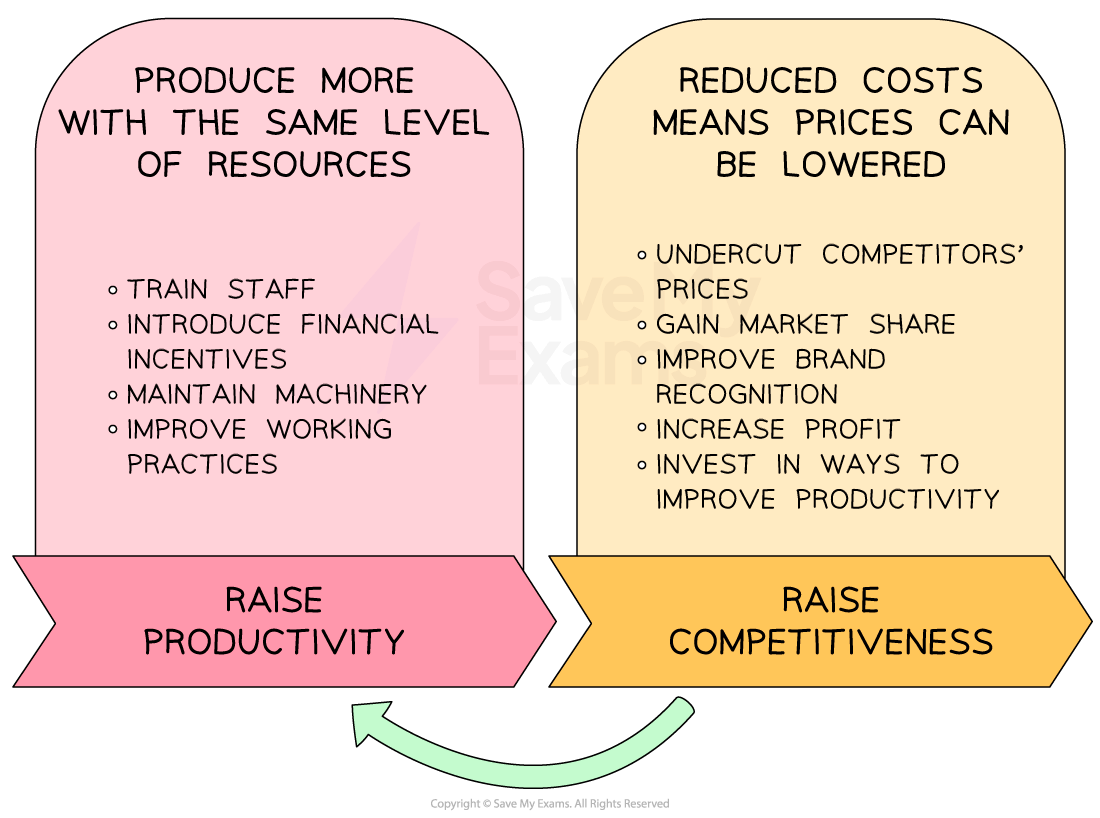

The link between productivity and competitiveness

Competitiveness refers to the ability of a business to maintain or grow its sales and market share, given the presence and actions of rivals

Businesses that increase their level of productivity (e.g. of workers or capital equipment) are likely to be more competitive

Productivity and competitiveness

Businesses that are competitive are likely to have the financial resources required to continue investing in improvements to their productivity

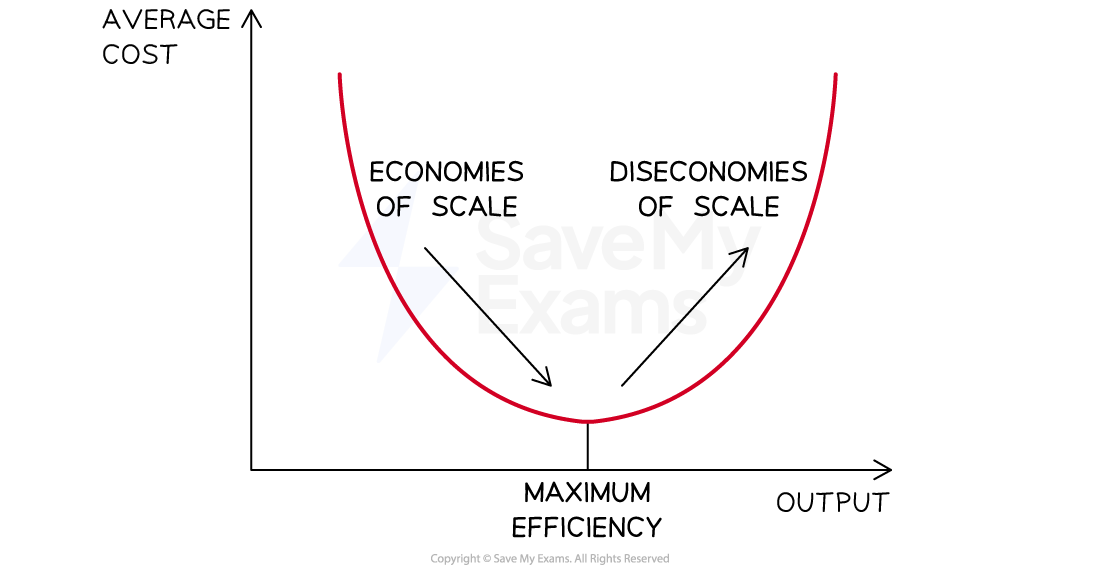

Understanding efficiency

Efficiency refers to the ability of a business to use its production resources as cost-effectively as possible

Efficiency is often measured in terms of the average cost per unit

The average cost per unit is calculated using the formula

Maximum efficiency is achieved when the cost per unit is at its lowest

Diagram showing maximum efficiency

The average cost curve shows that the most efficient level of production is achieved when:

Economies of scale are maximised

Total costs are spread across an optimum level of output

Diseconomies of scale are minimised

Factors that influence efficiency

Factors that can influence business efficiency

Factor | Explanation |

|---|---|

Standardisation of the production process |

|

Relocation or downsizing |

|

Investment in capital equipment |

|

Organisational restructuring |

|

Outsourcing |

|

Adoption of lean production techniques |

|

Capital-intensive and labour-intensive production

Labour-intensive production predominantly uses physical labour in the production of goods/services

The delivery of services is usually more labour-intensive than manufacturing

In countries where labour costs are low (e.g. Bangladesh), labour-intensive production is common

Small-scale production is likely to be labour-intensive

For example, UK schools are labour-intensive operations, as teachers plan and deliver lessons and provide pastoral support

Capital-intensive production predominantly uses machinery and technology in the production of goods and services

Large-scale production of standardised products is likely to be capital-intensive

Manufacturing in developed countries, where labour costs are relatively high, is likely to be capital-intensive

For example, automotive manufacturers such as Ford use robots and other production technology to manufacture vehicles, with supervisors overseeing the quality of output

Evaluation of labour-intensive and capital-intensive production

Type of production | Advantages | Disadvantages |

|---|---|---|

Capital-intensive |

|

|

Labour-intensive |

|

|

Unlock more, it's free!

Did this page help you?